Product Description

Water-Cooling Vacuum Pump Rotary Portable Industrial Mini Vane Scroll Reciprocating Diaphragm Centrifugal Positive Displacement Best Suppliers DC AC Vacuum Pump

water vacuum pump

Liquid Ring Vacuum Pump Working Principle. The vacuum pump consisting an impeller which is located eccentric to the cylinder body(Vacuum pump housing). Vacuum is created in the vacuum pump by using a liquid seal. ... When the impeller starts to rotate, the liquid is starts move outward by centrifugal force.

Water ring vacuum pump is a common type of liquid ring vacuum pump. Water ring is a rotor with multi-blades eccentrically installed in the pump shell. When it rotates, it throws liquid into the pump and forms a liquid ring concentric with the pump shell. The liquid ring and the rotor blade form a rotating variable capacity vacuum pump with periodic volume change. When the working liquid is water, it is called water Ring vacuum pump. There are many kinds of water ring vacuum pumps with different prices. .Among them, 2BV is more cost-effective. The type selection of water ring vacuum pump should be based on your on-site process, the required vacuum degree and the amount of air pumping required.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Oil or Not: | Oil Free |

|---|---|

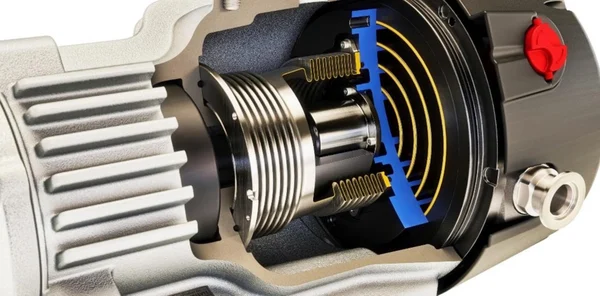

| Structure: | Rotary Vacuum Pump |

| Exhauster Method: | Entrapment Vacuum Pump |

| Vacuum Degree: | Vacuum |

| Work Function: | Mainsuction Pump |

| Working Conditions: | Dry |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Can scroll vacuum pumps be integrated into existing industrial systems and processes?

Yes, scroll vacuum pumps can be integrated into existing industrial systems and processes. Here's a detailed explanation:

Scroll vacuum pumps offer several features and characteristics that make them well-suited for integration into existing industrial systems and processes:

1. Compact Design:

Scroll vacuum pumps have a compact design and a smaller footprint compared to some other types of vacuum pumps. This makes them easier to install in existing systems where space may be limited. The compact size allows for flexible placement and integration into different configurations.

2. Versatility:

Scroll vacuum pumps are versatile and can handle a wide range of applications and processes across various industries. They are compatible with processes such as vacuum deposition, drying, degassing, distillation, and more. This versatility makes it easier to integrate scroll pumps into existing systems that may have diverse process requirements.

3. Multiple Connection Options:

Scroll vacuum pumps are designed to offer multiple connection options. They typically have standard inlet and outlet connections, allowing for easy integration into existing vacuum systems or processes. These connections can be customized or adapted as needed to ensure compatibility with the existing system's piping and components.

4. Control and Monitoring Capabilities:

Many scroll vacuum pumps come with built-in control and monitoring features. These can include digital interfaces, remote control capabilities, and real-time monitoring of operating parameters. These features facilitate the integration of scroll pumps into existing industrial systems and allow for seamless communication with other system components and control systems.

5. Retrofitting Options:

In some cases, scroll vacuum pumps can be retrofitted into existing systems as a replacement for older or less efficient vacuum pumps. Retrofitting involves modifying or adapting the system to accommodate the new pump. This can be a cost-effective solution for upgrading the vacuum performance of an existing system without significant redesign or disruption.

6. Compatibility with Different Environments:

Scroll vacuum pumps are designed to operate reliably in a wide range of environments, including industrial settings. They can withstand demanding conditions such as high temperatures, humidity, or vibration, which are commonly encountered in industrial processes. This compatibility ensures that scroll pumps can seamlessly integrate into existing systems without compromising performance or reliability.

When considering the integration of scroll vacuum pumps into existing industrial systems, it is important to assess specific requirements, such as the required pumping speed, ultimate vacuum level, compatibility with process gases, and any specific environmental considerations. Consulting with the pump manufacturer or a knowledgeable supplier can provide valuable guidance on selecting the appropriate scroll pump model and optimizing its integration into the existing system.

By leveraging the compact design, versatility, connection options, control capabilities, retrofitting possibilities, and compatibility with different environments, scroll vacuum pumps can be successfully integrated into existing industrial systems and processes, enhancing their vacuum performance and overall efficiency.

Do scroll vacuum pumps require water cooling or air cooling systems?

Scroll vacuum pumps can be designed to utilize either water cooling or air cooling systems. Here's a detailed explanation:

Water Cooling Systems:

Some scroll vacuum pumps are equipped with water cooling systems to dissipate the heat generated during operation. Water cooling offers efficient heat removal and helps maintain the pump at optimal operating temperatures. These pumps typically have connections for water inlet and outlet, allowing the circulation of cooling water through the pump's heat exchanger or jacket.

Water cooling systems are commonly used in applications where the pump operates at higher duty cycles or when the ambient temperature is relatively high. They are particularly advantageous when there is a need for continuous or extended operation at elevated vacuum levels, as water cooling provides effective heat dissipation and prevents overheating of the pump.

Air Cooling Systems:

Alternatively, some scroll vacuum pumps utilize air cooling systems. These pumps rely on the circulation of ambient air to dissipate the heat generated during operation. Air cooling systems typically incorporate cooling fins or fans to enhance heat transfer and maintain the pump within the acceptable temperature range.

Air cooling systems are commonly used in applications where water availability or infrastructure is limited. They are suitable for situations where the pump duty cycle is lower, and the operating conditions do not result in excessive heat generation.

Selection Considerations:

When choosing between water cooling and air cooling systems for a scroll vacuum pump, several factors should be considered:

- Duty Cycle: The duty cycle of the pump, which refers to the ratio of operating time to resting time, can influence the heat generation. Higher duty cycles may require water cooling for efficient heat dissipation.

- Operating Environment: The ambient temperature and availability of water resources in the operating environment should be assessed. Water cooling may be preferred in high-temperature environments or when water is readily available.

- Application Requirements: The specific requirements of the application, including desired vacuum level, pumping speed, and operating conditions, should be considered to determine the appropriate cooling system.

- Maintenance and Infrastructure: The availability of maintenance resources, infrastructure for water circulation, and any specific facility requirements should be evaluated when selecting the cooling system.

It's essential to consult the manufacturer's specifications and guidelines to determine the recommended cooling system for a particular scroll vacuum pump model. This ensures optimal performance, longevity, and reliability of the pump in the intended application.

What are the primary advantages of using scroll vacuum pumps?

Scroll vacuum pumps offer several advantages that make them a preferred choice in various applications. Here's a detailed explanation of the primary advantages of using scroll vacuum pumps:

1. Oil-Free Operation:

One of the significant advantages of scroll vacuum pumps is their oil-free operation. Unlike some other types of vacuum pumps, scroll pumps do not require oil for lubrication or sealing purposes. The interlocking scrolls create a sealing mechanism without the need for any lubricating medium. This eliminates the risk of oil contamination in sensitive applications, such as semiconductor manufacturing or laboratory environments, where oil-free conditions are crucial. It also reduces maintenance requirements, as there is no need for oil changes or monitoring oil levels.

2. High Efficiency:

Scroll vacuum pumps are known for their high efficiency. The continuous spiral motion of the scrolls ensures smooth operation and minimizes energy losses. The absence of frictional parts, such as piston rings or vanes, reduces internal losses and improves overall efficiency. Scroll pumps can achieve high pumping speeds and are capable of reaching deep vacuum levels. Their efficiency makes them suitable for applications where fast evacuation or high vacuum levels are required, such as in analytical instruments or in the production of electronic components.

3. Low Noise and Vibration:

Scroll vacuum pumps operate quietly and generate minimal vibrations. The spiral motion of the scrolls results in a smooth and continuous operation, reducing noise levels compared to other types of pumps. The absence of reciprocating parts, such as pistons or vanes, further contributes to the low noise and vibration levels. This characteristic is particularly advantageous in applications where noise reduction and minimal vibration are essential, such as in medical environments, laboratories, or research facilities.

4. Compact Size:

Scroll vacuum pumps are compact in size, making them suitable for applications where space is limited. Their small footprint allows for easy integration into existing systems or equipment. The compact size is especially beneficial in portable or handheld devices, where size and weight considerations are crucial. The compact design of scroll pumps also simplifies installation and maintenance, as they require less space and can be easily maneuvered or relocated as needed.

5. Minimal Maintenance:

Scroll vacuum pumps require minimal maintenance compared to some other vacuum pump types. The absence of oil eliminates the need for oil changes or monitoring oil levels. Scroll pumps typically have a simple design with fewer moving parts, reducing the risk of mechanical failure and the need for frequent repairs. This results in lower maintenance costs and less downtime, contributing to increased productivity and efficiency in various applications.

6. Clean and Contamination-Free:

Scroll vacuum pumps offer clean and contamination-free operation. The absence of oil means there is no risk of oil contamination in the evacuated environment, making them suitable for applications where maintaining a clean and pure atmosphere is critical. This is particularly important in industries such as semiconductor manufacturing, pharmaceuticals, or food processing, where even the slightest contamination can have significant consequences. The clean operation of scroll pumps ensures the integrity and quality of the final products.

7. Reliable Performance:

Scroll vacuum pumps are known for their reliable performance. The simplicity of their design, with fewer moving parts, reduces the risk of mechanical failure and improves overall reliability. Scroll pumps can operate continuously for extended periods without significant performance degradation. Their reliable performance makes them suitable for critical applications where consistent and dependable vacuum generation is essential.

In summary, the primary advantages of using scroll vacuum pumps include oil-free operation, high efficiency, low noise and vibration levels, compact size, minimal maintenance requirements, clean and contamination-free operation, and reliable performance. These advantages make scroll vacuum pumps a preferred choice in various industries and applications, ranging from semiconductor manufacturing and laboratories to medical equipment and research facilities.

editor by CX 2024-03-22