Product Description

Product Description

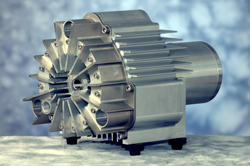

GWT Foreline Filter

Technical Specifications

| Model | GWT25 | GWT40 | |

| Operating Pressure | Pa | 1~105 | 1~105 |

| Efficiency | % | ≥99 | ≥99 |

| Particle Size Flitered | µm | ≥2~5 | ≥2~5 |

| Filter Element | Paper, or polyester | Paper, or polyester | |

| In/Exhaust Flange | KF25/KF25 | KF40/KF40 | |

| Weight | kg | 1.35 | 2.45 |

Dimensions

| A | B | C | D | E | |

| GWT25 | φ147 | 96 | 138 | KF 25 | 109 |

| GWT40 | φ187 | 142 | 199 | KF 40 | 132 |

Applications

Coating, pharmaceutical, food, ceramics and hglass, vacuum furnaces, vacuum packing

Oil free Scroll Vauum Pump

Company Profile

GEOWELL VACUUM CO.,LTD. is a HI-TECH enterprise in China dedicating in manufacturing, research and development, marketing of oil free scroll vacuum pumps and vacuum compressors since 2002. GEOWELL has been providing users and partners with premium quality products that are efficient and dependable, GEOWELL believe the integration of high performance and high reliability product and service will bring the highest value to both our customers and ourselves.

FAQ

Q: How long can I get the feedback after we sent the inquiry?

A: We will reply you within 12 hours in working day.

Q: Are you direct manufacturer?

A: Yes, we are direct manufacturer with factory and international department; we manufacture and sell all our products by ourselves.

Q: When can you delivery the product to us?

A: Since we are a factory with large warehouse, we have abundant products in store, so we can delivery within 7 days after get your deposit.

Q: Can I add logo to the products?

A: Of course, but we usually have quantity requirement. You can contact with us for details.

Q: How to guarantee the quality and after sales service of your products?

A: We conduct strict detection during production from raw material come in to product delivering shipment. Every product must go through 4 steps inspection from casting, machining, assembling, and performance testing within our factory before shipment, also intact packaging test are insured.

Q: What is your warranty term?

A: There is a 12 months warranty for our export products from the date of shipment. If warranty has run out, our customer should pay for the replacement part.

Q: Is the sample available?

A: Yes, usually we send our samples by Fedex, DHL, TNT, UPS, EMS, SF, Depon, it will take around 3 to 4 days for our customer receive them, but customer will charge all cost related to the samples, such as sample cost and air freight. We will refund our customer the sample cost after receiving the order.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Foreline Filter |

|---|---|

| Standard or Nonstandard: | Standard |

| Outlet Size: | KF25 |

| Power Source: | Electric |

| Color: | black |

| Application: | Oil free scroll vacuum pump |

| Customization: |

Available

|

|

|---|

Are scroll vacuum pumps environmentally friendly and compliant with regulations?

Scroll vacuum pumps are considered relatively environmentally friendly compared to some other types of vacuum pumps. Here's a detailed explanation:

Environmental Friendliness:

Scroll vacuum pumps offer several features that contribute to their environmental friendliness:

- Oil-Free Operation: Many scroll vacuum pumps are designed for oil-free operation. This eliminates the risk of oil contamination and the release of oil vapor or aerosols into the environment. Oil-free operation is particularly important in applications where a clean and particle-free vacuum environment is required, such as semiconductor manufacturing or research.

- Low Energy Consumption: Scroll pumps are known for their energy efficiency. They typically consume less energy compared to other vacuum pump technologies, resulting in reduced power consumption and lower environmental impact.

- Minimal Maintenance: Scroll vacuum pumps require minimal maintenance, which reduces the consumption of resources and minimizes waste generation associated with pump servicing or component replacement.

- Quiet Operation: Scroll pumps are designed to operate quietly, contributing to a more comfortable and environmentally friendly working environment by reducing noise pollution.

Regulatory Compliance:

Scroll vacuum pumps are designed and manufactured to comply with various regulations and standards, ensuring their safe and environmentally responsible operation. Some of the key regulations and standards that govern vacuum pumps include:

- European Union (EU) Regulations: Scroll vacuum pumps intended for sale or use within the European Union must comply with relevant directives, such as the Restriction of Hazardous Substances (RoHS) Directive and the Waste Electrical and Electronic Equipment (WEEE) Directive. These directives restrict the use of hazardous substances and promote the proper disposal and recycling of electronic equipment.

- International Electrotechnical Commission (IEC) Standards: IEC standards, such as IEC 61010 for electrical safety and IEC 61326 for electromagnetic compatibility, provide guidelines for the safe operation and performance of vacuum pumps and other laboratory equipment.

- Environmental Protection Agency (EPA) Regulations (United States): In the United States, scroll vacuum pumps must comply with environmental regulations enforced by the EPA, such as the Clean Air Act. These regulations aim to reduce emissions of ozone-depleting substances and other pollutants.

- Local and National Regulations: Depending on the jurisdiction, there may be additional local or national regulations governing the use, disposal, or emissions of vacuum pumps. Manufacturers ensure compliance with these regulations to meet the requirements of specific markets.

It is important to consult the manufacturer's specifications, certifications, and compliance statements to ensure that a particular scroll vacuum pump model meets the necessary environmental and regulatory standards for a given application or jurisdiction.

By choosing scroll vacuum pumps with oil-free operation, energy efficiency, minimal maintenance requirements, and compliance with regulations, users can contribute to a more environmentally friendly and sustainable vacuum system.

What are the maintenance requirements for scroll vacuum pumps, and are they user-friendly?

Scroll vacuum pumps have relatively low maintenance requirements and are generally considered user-friendly. Here's a detailed explanation:

1. Maintenance Requirements:

Scroll vacuum pumps require regular maintenance to ensure optimal performance and longevity. The specific maintenance tasks may vary depending on the pump model and manufacturer's recommendations. However, the common maintenance requirements for scroll vacuum pumps include:

a. Filter Cleaning/Replacement: Scroll vacuum pumps often incorporate inlet filters to prevent debris and particulates from entering the pump. These filters may need periodic cleaning or replacement to maintain proper airflow and prevent clogging.

b. Oil Inspection/Change (If Applicable): Some scroll vacuum pumps may require oil lubrication for bearing or sealing purposes. In such cases, regular oil inspection and oil change may be necessary to ensure proper lubrication and prevent contamination.

c. Seal Inspection/Replacement: Scroll vacuum pumps utilize seals to maintain the pressure difference between the inlet and outlet. Over time, these seals may wear out and require inspection or replacement to prevent leaks and maintain pump efficiency.

d. Overall Inspection and Cleaning: Regular visual inspections are recommended to check for any signs of wear, damage, or buildup of contaminants. Cleaning the pump surfaces and removing any accumulated debris or dust can help maintain optimal performance.

2. User-Friendly Nature:

Scroll vacuum pumps are generally considered user-friendly due to the following reasons:

a. Easy Installation: Scroll vacuum pumps are compact and lightweight, making them easy to install and integrate into vacuum systems. They often come with user manuals or documentation that provide step-by-step instructions for installation.

b. Simple Operation: Scroll vacuum pumps have a straightforward operating principle with minimal moving parts. They typically require no adjustments or tuning during operation, making them easy to use for both novice and experienced users.

c. Minimal Maintenance: Compared to some other types of vacuum pumps, scroll vacuum pumps have relatively low maintenance requirements. The maintenance tasks are typically simple and can be performed without specialized tools or extensive technical knowledge.

d. Safety Features: Scroll vacuum pumps often incorporate safety features such as over-temperature protection or automatic shutdown mechanisms to prevent damage or accidents. These features enhance user safety and contribute to their user-friendly nature.

Overall, scroll vacuum pumps have manageable maintenance requirements and are considered user-friendly due to their ease of installation, simple operation, minimal maintenance needs, and incorporation of safety features. Regular adherence to the manufacturer's maintenance guidelines ensures optimal performance and extends the lifespan of the pump.

editor by Dream 2024-04-19