Product Description

Product Description

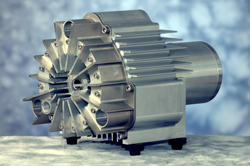

| ·The use of oil-free intermediate seal, multiple sealed way to ensure the high clean vacuum environment in the rotor chamber. ·Advanced processing to ensure the good geometrical symmetry ofthe rotors, as well as low noise and long service life. ·Special shaft seal is used to achieve the long stable running without oil leakage. ·The BSJ-L series is made of al-aluminum alloy, heat sink, corrosion resistance, and eficient energy saving.The Bs-LC series is made of cast iron. The unigue liquid coupling method enables the pump to start directly under the atmosphere, which greatly reduces the time of pumping ·Compact structure, light weight, and small volume. |

Product Parameters

Installation Instructions

Related Products

Packaging & Shipping

About Us

FAQ

|

Frequently Asked Questions (FAQ) About Our Products 1-What types of vacuum pumps do you offer? We supply a wide range of vacuum pumps, including rotary vane, diaphragm, screw, and turbo molecular pump, suitable for various applications. 2-Can your vacuum valves be used in any installation? Our vacuum valves, including gate, ball, butterfly, and check valves, are designed for versatility across numerous vacuum installations. Please consult our sales engineers for the best fit for your system. 3-Do you provide custom vacuum components? Yes, we can supply custom vacuum components tailored to your specific requirements. Contact us with your specifications for further assistance. Ordering and Shipping 4-How can I place an order? Orders can be placed directly through our website, via email, or by contacting our sales team. 5-Do you ship internationally? Absolutely! We provide global shipping options. Shipping costs and times will vary depending on your location and the size of your order. 6-What payment methods do you accept? We accept various payment methods, including bank transfers, credit/debit cards, and select online payment platforms. Please consult our sales team. Technical Support and Services 7-Do you offer installation services for your products? While we primarily supply vacuum products, we can recommend trusted partners for installation services. For certain regions, installation consultation may be available. Please consult our sales team for the details. 8-How can I get technical support for a product? Technical support is available through our website's support section, via email, or by phone. Our team of experts is ready to assist you with any queries or issues. Miscellaneous 9-How can I receive updates on new products and promotions? You can subscribe to our newsletter through our website to receive the latest product updates and promotional offers. 10-Do you offer discounts for bulk orders? Yes, we offer discounts for bulk orders. Please contact our sales team for more information on bulk order pricing. 11-How can I become a distributor for your products? We're always looking to expand our distribution network. If you're interested in becoming a distributor, please contact us to discuss the application process. |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Warranty: | 1 Year |

|---|---|

| Oil or Not: | Oil |

| Structure: | Rotary Vacuum Pump |

| Exhauster Method: | Positive Displacement Pump |

| Vacuum Degree: | Vacuum |

| Work Function: | Pre-Suction Pump |

| Samples: |

US$ 3800/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What is the cost range for scroll vacuum pumps, and how does it vary with capacity?

The cost of scroll vacuum pumps can vary depending on various factors, including the pump's capacity, brand, features, and market conditions. Here's a detailed explanation:

Cost Range:

The cost range for scroll vacuum pumps can vary significantly. On the lower end, smaller and lower-capacity scroll pumps can be found in the range of a few hundred to a few thousand dollars. These pumps are typically suitable for applications with lower pumping speed requirements.

As the capacity and pumping speed increase, the cost of scroll vacuum pumps tends to rise. Higher-capacity scroll pumps, designed for industrial or demanding applications, can range from several thousand dollars to tens of thousands of dollars.

Variation with Capacity:

The cost of scroll vacuum pumps generally increases with their capacity or pumping speed. Higher-capacity pumps require more robust construction, larger motors, and enhanced performance, which contribute to their higher cost.

The capacity of scroll vacuum pumps is often measured in terms of the pumping speed, expressed in liters per second (l/s) or cubic meters per hour (m³/h). As a general trend, pumps with higher pumping speeds have higher costs compared to pumps with lower pumping speeds.

However, it's important to note that the relationship between capacity and cost can vary across different manufacturers and models. Some manufacturers may offer pumps with similar capacities but at different price points due to variations in features, quality, or brand reputation.

Additional Cost Factors:

While capacity is a significant factor influencing the cost of scroll vacuum pumps, other factors can also contribute to price variations:

- Brand: Well-established and reputable brands often command higher prices due to their reputation for quality, performance, and customer support.

- Features and Technology: Advanced features, such as integrated control systems, digital interfaces, or remote monitoring capabilities, can increase the cost of scroll pumps compared to basic models.

- Materials and Construction: Pumps constructed from high-quality materials and designed for durability and reliability may have higher costs compared to pumps with more economical construction.

- Market Conditions: Market demand, competition, and economic factors can influence the pricing of scroll vacuum pumps. Prices may fluctuate over time due to market dynamics.

It is recommended to consult with suppliers or manufacturers to obtain specific pricing information for scroll vacuum pumps based on the desired capacity and any additional requirements. They can provide detailed quotations and assist in selecting the most suitable pump within the desired budget.

By considering the capacity, features, and cost factors, users can make informed decisions when choosing scroll vacuum pumps that meet their application requirements and budget constraints.

Are there oil-free options available for scroll vacuum pumps?

Yes, there are oil-free options available for scroll vacuum pumps. Here's a detailed explanation:

Traditionally, scroll vacuum pumps have utilized oil lubrication for sealing and bearing purposes. However, due to the increasing demand for oil-free vacuum solutions in various industries, manufacturers have developed oil-free versions of scroll vacuum pumps.

Oil-Free Scroll Vacuum Pumps:

Oil-free scroll vacuum pumps are designed to operate without the need for oil lubrication. Instead of relying on oil to create a seal and reduce internal friction, these pumps utilize dry-running mechanisms and specialized sealing materials to achieve reliable and efficient vacuum performance.

Advantages of Oil-Free Scroll Vacuum Pumps:

Oil-free scroll vacuum pumps offer several advantages, including:

a. Elimination of Oil Contamination: By eliminating oil lubrication, oil-free scroll vacuum pumps prevent the risk of oil contamination in the pumped gases or the surrounding environment. This is particularly important in applications where oil vapor or particles can adversely affect the process or product being handled.

b. Reduced Maintenance: Oil-free scroll vacuum pumps generally require less maintenance compared to their oil-lubricated counterparts. Without the need for oil changes, oil monitoring, or oil-related maintenance tasks, the overall maintenance requirements are simplified.

c. Environmentally Friendly: Oil-free scroll vacuum pumps are considered more environmentally friendly as they eliminate the need for oil disposal or recycling. They help reduce the carbon footprint and minimize the impact on the ecosystem.

d. Cost Savings: While the initial purchase cost of oil-free scroll vacuum pumps may be higher compared to oil-lubricated models, the long-term cost savings can be significant. The elimination of oil-related maintenance, reduced downtime, and improved process efficiency can result in overall cost savings.

Applications of Oil-Free Scroll Vacuum Pumps:

Oil-free scroll vacuum pumps find applications in various industries and processes, including:

- Semiconductor manufacturing - Analytical instruments - Pharmaceuticals and biotechnology - Food and beverage packaging - Electronics assembly - Research laboratories - Environmental monitoring - Vacuum drying - Leak detection - and more.

It's important to note that while oil-free scroll vacuum pumps offer numerous advantages, their performance specifications, such as pumping speed and ultimate vacuum levels, may differ from oil-lubricated scroll pumps. It's essential to select the appropriate pump based on the specific application requirements and consult the manufacturer's guidelines for proper operation and maintenance.

How does the scroll design contribute to the reliability of these pumps?

The scroll design of vacuum pumps plays a significant role in enhancing their reliability. Here's an explanation of how the scroll design contributes to the reliability of these pumps:

1. Sealed System:

The scroll design features two interleaved spiral scrolls, one fixed and one orbiting. The interaction between these scrolls creates a series of crescent-shaped chambers. As the orbiting scroll moves, these chambers decrease in size, compressing and expelling gases. The tightly sealed system of the scroll design ensures minimal leakage, preventing the entry of contaminants and maintaining a consistent vacuum level. This sealed system enhances the reliability of scroll vacuum pumps by minimizing the risk of performance degradation and ensuring continuous and efficient operation.

2. Oil-Free Operation:

One of the key advantages of scroll vacuum pumps is their oil-free operation. Unlike other types of pumps that rely on oil lubrication, scroll pumps utilize a dry mechanism. The scroll design eliminates the need for oil lubrication by using non-contacting, self-lubricating materials such as PTFE (polytetrafluoroethylene) or carbon. This eliminates the risk of oil contamination in the pumped gases or the vacuum chamber. The absence of oil also reduces maintenance requirements and enhances the reliability of the pumps by eliminating the potential for oil-related issues, such as oil degradation, leaks, or mechanical failures.

3. Minimal Moving Parts:

The scroll design features a relatively simple construction with minimal moving parts. Compared to other types of pumps, scroll vacuum pumps have fewer components that can wear out or malfunction. This reduces the likelihood of mechanical failures and improves the overall reliability of the pumps. The simplicity of the scroll design also contributes to ease of maintenance and servicing, further enhancing their reliability and uptime.

4. Low Vibration and Noise Levels:

The scroll design of vacuum pumps results in smooth and quiet operation. The absence of reciprocating pistons or vanes, which are common in other pump designs, reduces vibration levels. This lower vibration minimizes the stress on pump components, reducing wear and tear and improving the overall reliability. Additionally, the low noise levels of scroll pumps make them suitable for applications that require a quiet working environment, such as laboratories or medical facilities.

5. Contamination Resistance:

The scroll design of vacuum pumps offers inherent contamination resistance. The absence of oil lubrication eliminates the risk of oil carryover or oil-related contamination. Additionally, the sealed system and non-contacting scroll surfaces reduce the chances of particulate contamination or wear debris generation. This contamination resistance contributes to the long-term reliability of the pumps by minimizing the potential for performance degradation or damage to sensitive components.

In summary, the scroll design of vacuum pumps enhances their reliability through a sealed system, oil-free operation, minimal moving parts, low vibration and noise levels, and contamination resistance. These factors make scroll vacuum pumps a reliable choice for various industrial applications.

editor by Dream 2024-05-07