Product Description

Technical Parameters

If you want to obtain more parameter information, please contact us

Product Overview

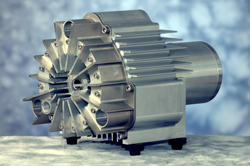

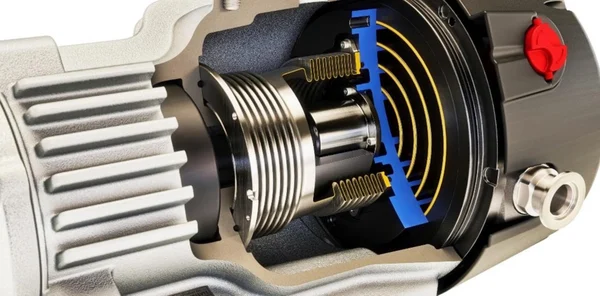

Grease lubricated molecular pump is a kind of mechanical vacuum pump which achieves pumping through the relative high speed rotation of multi-stage dynamic and static turbine vanes. This turbine molecular pump has the characteristics of large pumping speed and high compression ratio in the molecular flow area, and it is more energy-saving than diffusion pump and no oil vapor pollution.

Why Choose Us

About US

Our factory is a designated internship base of ZheJiang HangZhou University and a scientific research enterprise of East China University of Technology. Each production line of the factory is equipped with imported advanced equipment to ensure the continuous stability of product quality, and continuously innovate and develop products in the vacuum field to provide customers with superior quality Of vacuum products.

Packaging & Shipping

Related Products

Exhibition

FAQ

|

Frequently Asked Questions (FAQ) About Our Products 1-What types of vacuum pumps do you offer? We supply a wide range of vacuum pumps, including rotary vane, diaphragm, screw, and turbo molecular pump, suitable for various applications. 2-Can your vacuum valves be used in any installation? Our vacuum valves, including gate, ball, butterfly, and check valves, are designed for versatility across numerous vacuum installations. Please consult our sales engineers for the best fit for your system. 3-Do you provide custom vacuum components? Yes, we can supply custom vacuum components tailored to your specific requirements. Contact us with your specifications for further assistance. Ordering and Shipping 4-How can I place an order? Orders can be placed directly through our website, via email, or by contacting our sales team. 5-Do you ship internationally? Absolutely! We provide global shipping options. Shipping costs and times will vary depending on your location and the size of your order. 6-What payment methods do you accept? We accept various payment methods, including bank transfers, credit/debit cards, and select online payment platforms. Please consult our sales team. Technical Support and Services 7-Do you offer installation services for your products? While we primarily supply vacuum products, we can recommend trusted partners for installation services. For certain regions, installation consultation may be available. Please consult our sales team for the details. 8-How can I get technical support for a product? Technical support is available through our website's support section, via email, or by phone. Our team of experts is ready to assist you with any queries or issues. Miscellaneous 9-How can I receive updates on new products and promotions? You can subscribe to our newsletter through our website to receive the latest product updates and promotional offers. 10-Do you offer discounts for bulk orders? Yes, we offer discounts for bulk orders. Please contact our sales team for more information on bulk order pricing. 11-How can I become a distributor for your products? We're always looking to expand our distribution network. If you're interested in becoming a distributor, please contact us to discuss the application process. |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Warranty: | 1 Year |

|---|---|

| Inlet Flange: | ISO-K200 or CF200 |

| Power Source: | Electric |

| Lubrication: | Grease |

| Certification: | ISO9001 |

| Voltage: | 220V/380V |

| Samples: |

US$ 5500/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What safety features are typically integrated into scroll vacuum pump systems?

Scroll vacuum pump systems often incorporate several safety features to ensure safe and reliable operation. Here's a detailed explanation:

1. Overtemperature Protection:

Scroll vacuum pump systems typically include overtemperature protection mechanisms to prevent the pump from overheating. These safeguards can include temperature sensors that monitor the pump's operating temperature. If the temperature exceeds a predefined threshold, the system can activate alarms, shut down the pump, or initiate cooling measures to prevent damage to the pump or surrounding components.

2. Overpressure Protection:

To protect against excessive pressure, scroll vacuum pump systems may incorporate overpressure protection features. These features can include pressure relief valves or burst discs designed to vent or release excess pressure in the system. Overpressure protection mechanisms help prevent damage to the pump, system components, or potential hazards caused by pressure buildup.

3. Motor Overload Protection:

Scroll vacuum pump systems often include motor overload protection to safeguard the pump's motor from excessive current or power draw. Motor overload protection can be implemented through various means, such as thermal sensors or current monitoring devices. If the motor draws more current than normal or operates at a high temperature, the system can activate protective measures, such as shutting down the motor or triggering alarms.

4. Electrical Safety Measures:

Scroll vacuum pump systems adhere to electrical safety standards and incorporate safety measures to protect against electrical hazards. These can include features like ground fault circuit interrupters (GFCIs), circuit breakers, or surge protection devices to mitigate the risk of electric shocks, short circuits, or electrical fires.

5. Emergency Stop Buttons:

Many scroll vacuum pump systems feature emergency stop buttons or switches that allow users to immediately halt pump operation in case of emergencies or safety concerns. Activating the emergency stop button can quickly shut down the pump and associated equipment, preventing further risks or damages.

6. System Monitoring and Alarms:

Scroll vacuum pump systems may include monitoring capabilities and alarms to provide real-time information about the pump's performance and status. This can include monitoring parameters like vacuum level, temperature, pressure, and motor status. Alarms can be triggered if any of these parameters exceed safe operating limits, alerting users to potential issues or malfunctions.

7. Enclosure and Noise Reduction:

Scroll vacuum pump systems often feature enclosures or noise reduction measures to minimize noise levels during operation. These enclosures help create a quieter working environment and reduce noise pollution, contributing to workplace safety and comfort.

It is important to consult the manufacturer's specifications and guidelines for specific scroll vacuum pump systems to understand the safety features they incorporate. Manufacturers can provide detailed information on the safety mechanisms, recommended operating procedures, and any additional safety considerations specific to their systems.

By utilizing scroll vacuum pump systems with integrated safety features, users can ensure the protection of personnel, equipment, and the surrounding environment while achieving efficient and reliable vacuum performance.

Are there oil-free options available for scroll vacuum pumps?

Yes, there are oil-free options available for scroll vacuum pumps. Here's a detailed explanation:

Traditionally, scroll vacuum pumps have utilized oil lubrication for sealing and bearing purposes. However, due to the increasing demand for oil-free vacuum solutions in various industries, manufacturers have developed oil-free versions of scroll vacuum pumps.

Oil-Free Scroll Vacuum Pumps:

Oil-free scroll vacuum pumps are designed to operate without the need for oil lubrication. Instead of relying on oil to create a seal and reduce internal friction, these pumps utilize dry-running mechanisms and specialized sealing materials to achieve reliable and efficient vacuum performance.

Advantages of Oil-Free Scroll Vacuum Pumps:

Oil-free scroll vacuum pumps offer several advantages, including:

a. Elimination of Oil Contamination: By eliminating oil lubrication, oil-free scroll vacuum pumps prevent the risk of oil contamination in the pumped gases or the surrounding environment. This is particularly important in applications where oil vapor or particles can adversely affect the process or product being handled.

b. Reduced Maintenance: Oil-free scroll vacuum pumps generally require less maintenance compared to their oil-lubricated counterparts. Without the need for oil changes, oil monitoring, or oil-related maintenance tasks, the overall maintenance requirements are simplified.

c. Environmentally Friendly: Oil-free scroll vacuum pumps are considered more environmentally friendly as they eliminate the need for oil disposal or recycling. They help reduce the carbon footprint and minimize the impact on the ecosystem.

d. Cost Savings: While the initial purchase cost of oil-free scroll vacuum pumps may be higher compared to oil-lubricated models, the long-term cost savings can be significant. The elimination of oil-related maintenance, reduced downtime, and improved process efficiency can result in overall cost savings.

Applications of Oil-Free Scroll Vacuum Pumps:

Oil-free scroll vacuum pumps find applications in various industries and processes, including:

- Semiconductor manufacturing - Analytical instruments - Pharmaceuticals and biotechnology - Food and beverage packaging - Electronics assembly - Research laboratories - Environmental monitoring - Vacuum drying - Leak detection - and more.

It's important to note that while oil-free scroll vacuum pumps offer numerous advantages, their performance specifications, such as pumping speed and ultimate vacuum levels, may differ from oil-lubricated scroll pumps. It's essential to select the appropriate pump based on the specific application requirements and consult the manufacturer's guidelines for proper operation and maintenance.

What is a scroll vacuum pump, and how does it work?

A scroll vacuum pump is a type of positive displacement pump used to create a vacuum by removing gases or air from a sealed system. It operates based on the principle of two interlocking spiral-shaped scrolls or spirals that create a series of enclosed pockets or chambers. Here's a detailed explanation of how a scroll vacuum pump works:

1. Basic Design:

A scroll vacuum pump typically consists of two main components: a fixed scroll and an orbiting scroll. The fixed scroll remains stationary, while the orbiting scroll moves eccentrically within the fixed scroll. Both scrolls have interlocking profiles, and the shape of the profiles determines the operation of the pump.

2. Suction Stage:

At the start of the operation, the scrolls are in the outermost position, and the chambers between the scrolls are open to the inlet or suction side of the pump. As the orbiting scroll begins to rotate, it moves inward, causing the chambers to decrease in volume. This reduction in volume creates a suction effect, drawing the gas or air into the chambers from the inlet port. The suction stage is responsible for pulling the gas or air into the pump.

3. Compression Stage:

As the orbiting scroll continues to rotate, the chambers move toward the center of the scrolls, progressively reducing in size. This reduction in chamber volume compresses the gas or air trapped within the chambers. The gas or air becomes trapped between the scrolls as they interlock and move closer together. The compression stage increases the pressure within the trapped gas or air, progressively compressing it as the scrolls continue to rotate.

4. Discharge Stage:

Once the chambers reach the center of the scrolls, they move to the outermost position on the discharge side of the pump. At this stage, the compressed gas or air is forced out of the pump through the discharge port. The discharge stage completes a full rotation of the scrolls, expelling the compressed gas or air from the pump, creating a vacuum within the system.

5. Oil-Free Operation:

One significant advantage of scroll vacuum pumps is their oil-free operation. Unlike some other vacuum pump types, scroll pumps do not require oil for lubrication or sealing purposes. The interlocking scrolls create a sealing mechanism without the need for any lubricating medium. This oil-free operation eliminates the risk of oil contamination in sensitive applications and reduces maintenance requirements.

6. Efficiency and Noise:

Scroll vacuum pumps are known for their efficiency and low noise levels. The continuous spiral motion of the scrolls ensures smooth and quiet operation. Additionally, the absence of frictional parts and the use of precise manufacturing techniques contribute to their overall efficiency. Scroll pumps can achieve high pumping speeds and deep vacuum levels, making them suitable for various applications.

7. Applications:

Scroll vacuum pumps find applications in a wide range of industries. They are commonly used in laboratories, medical equipment, semiconductor manufacturing, analytical instruments, and other industries that require clean, oil-free vacuum systems. Their compact size, reliability, and low maintenance make them a popular choice in applications where quiet operation and minimal vibration are essential.

In summary, a scroll vacuum pump operates by using two interlocking scrolls to create a series of chambers that progressively decrease in volume, leading to gas or air suction, compression, and discharge. The oil-free operation, efficiency, low noise levels, and suitability for various applications make scroll vacuum pumps a widely used and reliable vacuum solution.

editor by CX 2024-04-17