Product Description

Product Description

GWSP Oil free Scroll Vacuum Pump

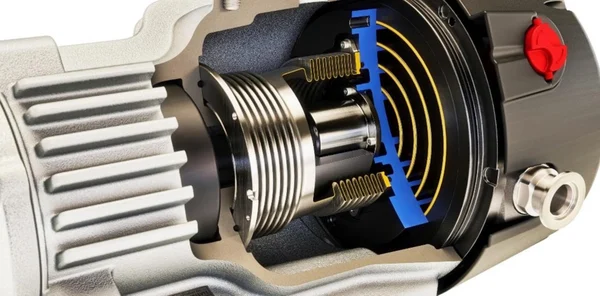

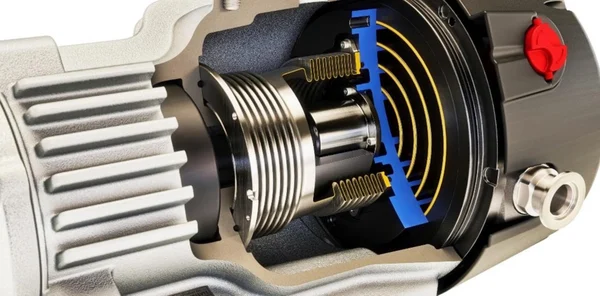

Working principle:

GWSP oil free scroll vacuum pump is constructed with pump head assembly, crank pin assembly, bracket assembly, air flush assembly,and exhaust valve assembly.Two spiral cylinders, 1 offset and orbiting against the other fixed with an offset of 180° to form several crescent-shaped pockets of different sizes. By means of an eccentric drive, the orbiting scroll is made to orbit about the fixed scroll, reducing the volume of the pockets and compressing gas from outside towards the inside thereby pumping the gas from vacuum chamber.

Basic informations:

1) Model: GWSP75 Oil free scroll vacuum pump

2) Ultimate vacuum pressure: 8.0Pa/0.08 mbar (abs.)

3) Max suction capacity: 50Hz-1.0L/s 60Hz-1.2L/s

Safety Precautions:

The GWSP series oil free scroll vacuum pumps are suitable for clean processes only.

Do not pump toxic, explosive, flammable or corrosive substances or substances which contain chemicals, solvents or particles.GEOWELL will not perform maintenance work on pumps which have used special gases or other hazardous substances.

Be sure the inlet gas temperature must be lower than 122 °F.

Technical Specifications

| Model | GWSP40 | GWSP75 | GWSP150 | GWSP300 | GWSP600 | GWSP1000 | ||

| Pumping Speed | 50Hz | l/s | 0.5 | 1.0 | 2.0 | 4.3 | 8.7 | 16.6 |

| m3/h | 1.8 | 3.6 | 7.2 | 15.5 | 31.3 | 59.8 | ||

| cfm | 1.1 | 2.1 | 4.3 | 9.3 | 18.7 | 35.8 | ||

| 60Hz | l/s | 0.6 | 1.2 | 2.4 | 5.1 | 10.4 | 20.0 | |

| m3/h | 2.2 | 4.3 | 8.6 | 18.3 | 37.4 | 71.6 | ||

| cfm | 1.3 | 2.5 | 5.1 | 10.9 | 22.3 | 42.8 | ||

| Ultimate Pressure | Torr | ≤1.1*10-1 | ≤6.0*10-2 | ≤4.5*10-2 | ≤1.9*10-2 | ≤7.5*10-3 | ≤7.5*10-3 | |

| psi | ≤2.2*10-3 | ≤1.2*10-3 | ≤9.0*10-4 | ≤3.8*10-4 | ≤1.5*10-4 | ≤1.5*10-4 | ||

| Pa | ≤15 | ≤8 | ≤6 | ≤2.6 | ≤1 | ≤1 | ||

| mbar | ≤1.5*10-1 | ≤8.0*10-2 | ≤6.0*10-2 | ≤2.6*10-2 | ≤1.0*10-2 | ≤1.0*10-2 | ||

| Noise Level | dB(A) | ≤54 | ≤57 | ≤57 | ≤60 | ≤61 | ≤65 | |

| Leakage | mbar·l/s | 1*10-7 | ||||||

| Max. Inlet/Exhaust Pressure | MPa | 0.1 / 0.13 | ||||||

| Ambient Operation Temp. | ºF | 41~104 | ||||||

| Motor 1 phase | Power | kW | 0.25 | 0.55 | 0.55 | 0.55 | 0.75 | -- |

| Voltage | V | 110~115 (60Hz),200~230 (50Hz) | -- | |||||

| Speed | rpm | 1425(50Hz),1725(60Hz) | -- | |||||

| Plug | North America, Europe, UK/Ireland, India | -- | ||||||

| Motor 3 phase | Power | kW | -- | 0.55 | 0.55 | 0.55 | 0.75 | 1.5 |

| Voltage | V | -- | 200~230 or 380~415 (50Hz),200~230 or 460 (60Hz) | |||||

| Speed | rpm | -- | 1425 (50Hz),1725 (60Hz) | |||||

| Inlet/Exhaust Flange | KF25/KF16 | KF40/KF16 | KF40/KF16*2 | |||||

| Dimensions | 1 phase | mm | 326*212*253 | 450*260*296 | 455*260*296 | 493*297*334 | 538*315*348 | -- |

| 3 phase | mm | -- | 450*260*296 | 455*260*296 | 493*297*334 | 538*315*348 | 576*450*402 | |

| Net Weight | 1 phase | kg | 15 | 21 | 22 | 29 | 36 | -- |

| 3 phase | kg | -- | 20 | 21 | 28 | 31 | 54 | |

| Cooling Type | Air cooled | |||||||

| Others | With air flush | |||||||

Features & Benefits

No oil clean vacuum.

No oil back-diffusion, no oil mist exhaust, provide clean vacuum environment

Wide product lineup.

Pumping speed covers 3~60 m3 /h, limited vacuum level 1~8 Pa

Suitable for all type of power supply around the world.

110/220/380/460V, 50/60Hz for choose

Low vibration, low noise.

57~65 dB(A), smooth operation

High efficiency, ease of maintenance.

No water cooled, no oil lubricated, no daily maintenance

Quality Control

CMM inspection system assures

fixed tolarance on dimension&shape

Pump Testing

Applications

Analyzing instrument and device.

Spectroscopy/scHangZhou electron microscopy.

Space environment simulation machine.

Helium Leak detector.

Mass spectrometer.

Cryopump regeneration.

Accelerators/synchrotrons.

Food and drug industry.

Freezing dryer.

Vacuum storage.

Medical equipment

Low temperature plasma sterilizer.

Vacuum storage.

Dental equipment.

Vacuum equipment.

Oil free ultrahigh vacuum unit

Oil free vacuum unit

Related Products

GWT25 Foreline Filter

Performance: Filter out the dust particles contained in the intake gas.

Application: Vacuum coating, food and drug processing, ceramic and glass manufacturing, vacuum CHINAMFG and vacuum packaging systems.

GWS16 Exhaust Silencer

Performance: Reduce exhaust noise from oil-free vacuum systems.

Application: Installation of oil free scroll vacuum pumps requires a quiet vacuum system.

GWMMK75 Major Maintenance Kit

Performance: Prolong the service life of the product.

Application: For the major maintenance of oil free scroll vacuum pump GWSP75.

GWTST75 Tip Seal Kit

Performance: Prolong the service life of the product.

Application: For the scheduled maintenance of oil free scroll vacuum pump GWSP75.

Company Profile

GEOWELL VACUUM CO.,LTD. is a HI-TECH enterprise in China dedicating in manufacturing, research and development, marketing of oil free scroll vacuum pumps and vacuum compressors since 2002. GEOWELL has been providing users and partners with premium quality products that are efficient and dependable, GEOWELL believe the integration of high performance and high reliability product and service will bring the highest value to both our customers and ourselves.

FAQ

Q: How long can I get the feedback after we sent the inquiry?

A: We will reply you within 12 hours in working day.

Q: Are you direct manufacturer?

A: Yes, we are direct manufacturer with factory and international department; we manufacture and sell all our products by ourselves.

Q: When can you delivery the product to us?

A: Since we are a factory with large warehouse, we have abundant products in store, so we can delivery within 7 days after get your deposit.

Q: Can I add logo to the products?

A: Of course, but we usually have quantity requirement. You can contact with us for details.

Q: How to guarantee the quality and after sales service of your products?

A: We conduct strict detection during production from raw material come in to product delivering shipment. Every product must go through 4 steps inspection from casting, machining, assembling, and performance testing within our factory before shipment, also intact packaging test are insured.

Q: What is your warranty term?

A: There is a 12 months warranty for our export products from the date of shipment. If warranty has run out, our customer should pay for the replacement part.

Q: Is the sample available?

A: Yes, usually we send our samples by Fedex, DHL, TNT, UPS, EMS, SF, Depon, it will take around 3 to 4 days for our customer receive them, but customer will charge all cost related to the samples, such as sample cost and air freight. We will refund our customer the sample cost after receiving the order.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Yes |

|---|---|

| Warranty: | 1 Years |

| Oil or Not: | Oil Free |

| Structure: | Scroll Pump |

| Exhauster Method: | a Pair of Vortex Plates |

| Vacuum Degree: | Low Vacuum |

| Customization: |

Available

|

|

|---|

What is the cost range for scroll vacuum pumps, and how does it vary with capacity?

The cost of scroll vacuum pumps can vary depending on various factors, including the pump's capacity, brand, features, and market conditions. Here's a detailed explanation:

Cost Range:

The cost range for scroll vacuum pumps can vary significantly. On the lower end, smaller and lower-capacity scroll pumps can be found in the range of a few hundred to a few thousand dollars. These pumps are typically suitable for applications with lower pumping speed requirements.

As the capacity and pumping speed increase, the cost of scroll vacuum pumps tends to rise. Higher-capacity scroll pumps, designed for industrial or demanding applications, can range from several thousand dollars to tens of thousands of dollars.

Variation with Capacity:

The cost of scroll vacuum pumps generally increases with their capacity or pumping speed. Higher-capacity pumps require more robust construction, larger motors, and enhanced performance, which contribute to their higher cost.

The capacity of scroll vacuum pumps is often measured in terms of the pumping speed, expressed in liters per second (l/s) or cubic meters per hour (m³/h). As a general trend, pumps with higher pumping speeds have higher costs compared to pumps with lower pumping speeds.

However, it's important to note that the relationship between capacity and cost can vary across different manufacturers and models. Some manufacturers may offer pumps with similar capacities but at different price points due to variations in features, quality, or brand reputation.

Additional Cost Factors:

While capacity is a significant factor influencing the cost of scroll vacuum pumps, other factors can also contribute to price variations:

- Brand: Well-established and reputable brands often command higher prices due to their reputation for quality, performance, and customer support.

- Features and Technology: Advanced features, such as integrated control systems, digital interfaces, or remote monitoring capabilities, can increase the cost of scroll pumps compared to basic models.

- Materials and Construction: Pumps constructed from high-quality materials and designed for durability and reliability may have higher costs compared to pumps with more economical construction.

- Market Conditions: Market demand, competition, and economic factors can influence the pricing of scroll vacuum pumps. Prices may fluctuate over time due to market dynamics.

It is recommended to consult with suppliers or manufacturers to obtain specific pricing information for scroll vacuum pumps based on the desired capacity and any additional requirements. They can provide detailed quotations and assist in selecting the most suitable pump within the desired budget.

By considering the capacity, features, and cost factors, users can make informed decisions when choosing scroll vacuum pumps that meet their application requirements and budget constraints.

Can scroll vacuum pumps be used in laboratory applications?

Yes, scroll vacuum pumps can be used in laboratory applications. Here's a detailed explanation:

Scroll vacuum pumps offer several features and advantages that make them suitable for various laboratory applications:

1. Oil-Free Operation:

Many laboratory applications require a clean and oil-free vacuum environment to maintain the integrity of samples, prevent contamination, and ensure accurate results. Scroll vacuum pumps are available in oil-free versions, eliminating the risk of oil vapor or particles contaminating the vacuum system and samples.

2. Low Vibration and Noise:

In laboratory settings where precision and sensitive measurements are crucial, low vibration and noise levels are important considerations. Scroll vacuum pumps operate with minimal vibration and produce less noise compared to some other types of vacuum pumps, making them suitable for laboratory environments.

3. Compact and Space-Efficient:

Laboratories often have limited space, and equipment that is compact and space-efficient is desirable. Scroll vacuum pumps are relatively compact in size and can be easily integrated into laboratory setups without occupying excessive space.

4. Ease of Use:

Scroll vacuum pumps are known for their user-friendly nature. They typically have simple operating procedures, require minimal adjustments or tuning, and are easy to install and operate. This is advantageous in laboratory settings where researchers and technicians may need to work with multiple instruments simultaneously.

5. Versatile Applications:

Scroll vacuum pumps find applications in a wide range of laboratory processes, including:

- Vacuum filtration

- Rotary evaporation

- Freeze drying

- Glove box systems

- Vacuum ovens

- Vacuum distillation

- Vacuum degassing

- Mass spectrometry

- Electron microscopy

- Gas chromatography

- and many more.

It's important to note that the suitability of a scroll vacuum pump for a specific laboratory application depends on the desired vacuum level, required pumping speed, compatibility with the gases or vapors being handled, and any additional requirements specific to the experimental or analytical techniques being employed.

Before selecting a scroll vacuum pump for laboratory use, it is advisable to consult the manufacturer's specifications and guidelines to ensure that the pump meets the specific requirements of the intended application.

What is a scroll vacuum pump, and how does it work?

A scroll vacuum pump is a type of positive displacement pump used to create a vacuum by removing gases or air from a sealed system. It operates based on the principle of two interlocking spiral-shaped scrolls or spirals that create a series of enclosed pockets or chambers. Here's a detailed explanation of how a scroll vacuum pump works:

1. Basic Design:

A scroll vacuum pump typically consists of two main components: a fixed scroll and an orbiting scroll. The fixed scroll remains stationary, while the orbiting scroll moves eccentrically within the fixed scroll. Both scrolls have interlocking profiles, and the shape of the profiles determines the operation of the pump.

2. Suction Stage:

At the start of the operation, the scrolls are in the outermost position, and the chambers between the scrolls are open to the inlet or suction side of the pump. As the orbiting scroll begins to rotate, it moves inward, causing the chambers to decrease in volume. This reduction in volume creates a suction effect, drawing the gas or air into the chambers from the inlet port. The suction stage is responsible for pulling the gas or air into the pump.

3. Compression Stage:

As the orbiting scroll continues to rotate, the chambers move toward the center of the scrolls, progressively reducing in size. This reduction in chamber volume compresses the gas or air trapped within the chambers. The gas or air becomes trapped between the scrolls as they interlock and move closer together. The compression stage increases the pressure within the trapped gas or air, progressively compressing it as the scrolls continue to rotate.

4. Discharge Stage:

Once the chambers reach the center of the scrolls, they move to the outermost position on the discharge side of the pump. At this stage, the compressed gas or air is forced out of the pump through the discharge port. The discharge stage completes a full rotation of the scrolls, expelling the compressed gas or air from the pump, creating a vacuum within the system.

5. Oil-Free Operation:

One significant advantage of scroll vacuum pumps is their oil-free operation. Unlike some other vacuum pump types, scroll pumps do not require oil for lubrication or sealing purposes. The interlocking scrolls create a sealing mechanism without the need for any lubricating medium. This oil-free operation eliminates the risk of oil contamination in sensitive applications and reduces maintenance requirements.

6. Efficiency and Noise:

Scroll vacuum pumps are known for their efficiency and low noise levels. The continuous spiral motion of the scrolls ensures smooth and quiet operation. Additionally, the absence of frictional parts and the use of precise manufacturing techniques contribute to their overall efficiency. Scroll pumps can achieve high pumping speeds and deep vacuum levels, making them suitable for various applications.

7. Applications:

Scroll vacuum pumps find applications in a wide range of industries. They are commonly used in laboratories, medical equipment, semiconductor manufacturing, analytical instruments, and other industries that require clean, oil-free vacuum systems. Their compact size, reliability, and low maintenance make them a popular choice in applications where quiet operation and minimal vibration are essential.

In summary, a scroll vacuum pump operates by using two interlocking scrolls to create a series of chambers that progressively decrease in volume, leading to gas or air suction, compression, and discharge. The oil-free operation, efficiency, low noise levels, and suitability for various applications make scroll vacuum pumps a widely used and reliable vacuum solution.

editor by CX 2024-04-16