Product Description

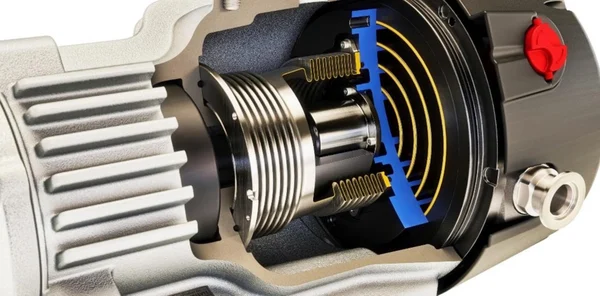

Industrial Vacuum Pump Air Oil Water Rotary Dry Portable Mini Scroll Reciprocating Diaphragm Centrifugal Positive Displacement DC AC Vacuum Pump

industrial vacuum pumps

Rotary vane: Rotary vane pumps are comprised of a series of vanes that are mounted to a rotor that turns inside a cavity. As the vanes rotate, centrifugal force extends them from their individual slots, forming compression cells that get larger to draw air in from the intake and smaller to push air out the exhaust.

Articulated piston: An articulated piston industrial vacuum pump operates in a manner similar to that of an automobile engine. As the piston moves downward inside the cylinder, air is drawn in through the intake valve. During the piston's upward stroke, the air is permitted to escape via an exhaust valve. Two spring-backed piston rings are used to seal the piston to the cylinder.

Screw: Rotary screw pumnps include 2 parallel rotary screws in the pump housing. The screws are synchronized to turn in opposite directions, which causes the compression action to occur. The gas is compressed in the direction of the pump's discharge port.

Liquid ring: Liquid ring pumps also operate via positive displacement. During operation, the pump's impeller rotates inside the pump casing. A rotating liquid ring then seals the impeller and its blades. Liquid is sucked into the compression chamber to keep the ring stable. Conveyed gas is compressed during each impeller revolution.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Oil or Not: | Oil Free |

|---|---|

| Structure: | Rotary Vacuum Pump |

| Exhauster Method: | Entrapment Vacuum Pump |

| Vacuum Degree: | Vacuum |

| Work Function: | Mainsuction Pump |

| Working Conditions: | Dry |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

What is the cost range for scroll vacuum pumps, and how does it vary with capacity?

The cost of scroll vacuum pumps can vary depending on various factors, including the pump's capacity, brand, features, and market conditions. Here's a detailed explanation:

Cost Range:

The cost range for scroll vacuum pumps can vary significantly. On the lower end, smaller and lower-capacity scroll pumps can be found in the range of a few hundred to a few thousand dollars. These pumps are typically suitable for applications with lower pumping speed requirements.

As the capacity and pumping speed increase, the cost of scroll vacuum pumps tends to rise. Higher-capacity scroll pumps, designed for industrial or demanding applications, can range from several thousand dollars to tens of thousands of dollars.

Variation with Capacity:

The cost of scroll vacuum pumps generally increases with their capacity or pumping speed. Higher-capacity pumps require more robust construction, larger motors, and enhanced performance, which contribute to their higher cost.

The capacity of scroll vacuum pumps is often measured in terms of the pumping speed, expressed in liters per second (l/s) or cubic meters per hour (m³/h). As a general trend, pumps with higher pumping speeds have higher costs compared to pumps with lower pumping speeds.

However, it's important to note that the relationship between capacity and cost can vary across different manufacturers and models. Some manufacturers may offer pumps with similar capacities but at different price points due to variations in features, quality, or brand reputation.

Additional Cost Factors:

While capacity is a significant factor influencing the cost of scroll vacuum pumps, other factors can also contribute to price variations:

- Brand: Well-established and reputable brands often command higher prices due to their reputation for quality, performance, and customer support.

- Features and Technology: Advanced features, such as integrated control systems, digital interfaces, or remote monitoring capabilities, can increase the cost of scroll pumps compared to basic models.

- Materials and Construction: Pumps constructed from high-quality materials and designed for durability and reliability may have higher costs compared to pumps with more economical construction.

- Market Conditions: Market demand, competition, and economic factors can influence the pricing of scroll vacuum pumps. Prices may fluctuate over time due to market dynamics.

It is recommended to consult with suppliers or manufacturers to obtain specific pricing information for scroll vacuum pumps based on the desired capacity and any additional requirements. They can provide detailed quotations and assist in selecting the most suitable pump within the desired budget.

By considering the capacity, features, and cost factors, users can make informed decisions when choosing scroll vacuum pumps that meet their application requirements and budget constraints.

Can scroll vacuum pumps be used in laboratory applications?

Yes, scroll vacuum pumps can be used in laboratory applications. Here's a detailed explanation:

Scroll vacuum pumps offer several features and advantages that make them suitable for various laboratory applications:

1. Oil-Free Operation:

Many laboratory applications require a clean and oil-free vacuum environment to maintain the integrity of samples, prevent contamination, and ensure accurate results. Scroll vacuum pumps are available in oil-free versions, eliminating the risk of oil vapor or particles contaminating the vacuum system and samples.

2. Low Vibration and Noise:

In laboratory settings where precision and sensitive measurements are crucial, low vibration and noise levels are important considerations. Scroll vacuum pumps operate with minimal vibration and produce less noise compared to some other types of vacuum pumps, making them suitable for laboratory environments.

3. Compact and Space-Efficient:

Laboratories often have limited space, and equipment that is compact and space-efficient is desirable. Scroll vacuum pumps are relatively compact in size and can be easily integrated into laboratory setups without occupying excessive space.

4. Ease of Use:

Scroll vacuum pumps are known for their user-friendly nature. They typically have simple operating procedures, require minimal adjustments or tuning, and are easy to install and operate. This is advantageous in laboratory settings where researchers and technicians may need to work with multiple instruments simultaneously.

5. Versatile Applications:

Scroll vacuum pumps find applications in a wide range of laboratory processes, including:

- Vacuum filtration

- Rotary evaporation

- Freeze drying

- Glove box systems

- Vacuum ovens

- Vacuum distillation

- Vacuum degassing

- Mass spectrometry

- Electron microscopy

- Gas chromatography

- and many more.

It's important to note that the suitability of a scroll vacuum pump for a specific laboratory application depends on the desired vacuum level, required pumping speed, compatibility with the gases or vapors being handled, and any additional requirements specific to the experimental or analytical techniques being employed.

Before selecting a scroll vacuum pump for laboratory use, it is advisable to consult the manufacturer's specifications and guidelines to ensure that the pump meets the specific requirements of the intended application.

What are the typical applications of scroll vacuum pumps across industries?

Scroll vacuum pumps find applications in a wide range of industries due to their unique advantages and capabilities. Here's a detailed explanation of the typical applications of scroll vacuum pumps across various industries:

1. Laboratories and Research Facilities:

Scroll vacuum pumps are extensively used in laboratories and research facilities for various applications. They are commonly employed in vacuum ovens, freeze dryers, rotary evaporators, and other laboratory equipment that require precise and controlled vacuum environments. Scroll pumps' oil-free operation ensures a clean and contamination-free atmosphere, making them suitable for sensitive experiments and analyses. Their low noise and vibration levels are also advantageous in research settings where a quiet environment is necessary.

2. Semiconductor Manufacturing:

In the semiconductor industry, scroll vacuum pumps play a crucial role in the fabrication and production of electronic components. They are used in processes such as physical vapor deposition (PVD), chemical vapor deposition (CVD), etching, and ion implantation. Scroll pumps provide the required vacuum conditions for these processes, ensuring the deposition or removal of materials with high precision. Their oil-free operation eliminates the risk of oil contamination in the semiconductor manufacturing process, ensuring the quality and reliability of the manufactured devices.

3. Analytical Instruments:

Scroll vacuum pumps are widely used in analytical instruments such as mass spectrometers, electron microscopes, and surface analysis equipment. These instruments require vacuum environments to operate efficiently and produce accurate results. Scroll pumps offer the necessary vacuum levels for sample preparation, ionization, and analysis. Their high pumping speed and deep vacuum capabilities make them suitable for rapid evacuation and maintaining the required vacuum conditions during analytical processes.

4. Medical and Pharmaceutical Applications:

In the medical and pharmaceutical industries, scroll vacuum pumps find applications in various areas. They are commonly used in medical sterilizers, vacuum ovens for drying pharmaceutical products, and vacuum concentrators for sample preparation. The oil-free operation of scroll pumps ensures the integrity and quality of medical devices, pharmaceutical products, and biological samples. Their low noise levels and compact size are advantageous in medical environments where space is limited, and a quiet atmosphere is necessary.

5. Food Processing and Packaging:

Scroll vacuum pumps are employed in the food processing and packaging industry for vacuum packaging, vacuum sealing, and degassing processes. They help extend the shelf life of food products by creating a vacuum environment that inhibits microbial growth and prevents oxidation. Scroll pumps are also used in food freeze-drying processes to remove moisture while maintaining the product's quality and nutritional value. Their clean and oil-free operation ensures the hygiene and safety of the food products.

6. Environmental and HVAC Systems:

Scroll vacuum pumps are used in environmental monitoring systems where they help create vacuum conditions for gas analysis and air quality measurement. They are also utilized in heating, ventilation, and air conditioning (HVAC) systems for vacuum evacuation during the installation or maintenance of HVAC units. The compact size and low noise levels of scroll pumps make them suitable for HVAC applications where space constraints and noise reduction are important considerations.

7. Automotive and Manufacturing:

In the automotive and manufacturing industries, scroll vacuum pumps find applications in processes such as vacuum molding, vacuum lifting, and vacuum forming. They provide the necessary vacuum conditions for molding or shaping materials, lifting heavy objects, and creating airtight seals. The oil-free operation of scroll pumps ensures that there is no risk of oil contamination in the manufactured products.

These are just a few examples of the typical applications of scroll vacuum pumps across industries. Their oil-free operation, high efficiency, low noise levels, and clean vacuum generation make them a versatile and reliable choice in various industrial sectors.

editor by CX 2024-03-11