Product Description

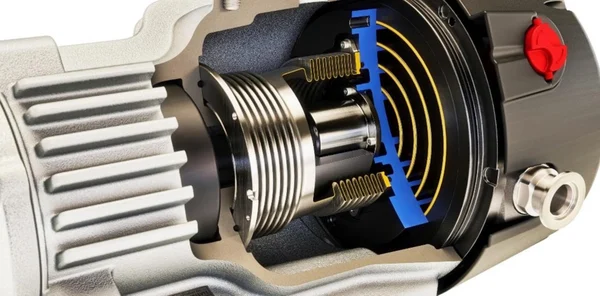

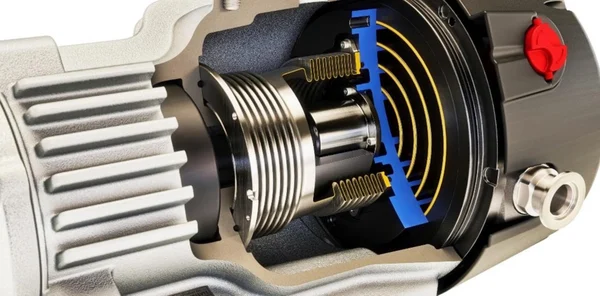

Dry Scroll Vacuum Pump RGP3

Product Description

The scroll vacuum pump is a new generation of oil-free mechanical pump, which has the advantages of simple structure, good sealing performance and high ultimate vacuum. As a high-tech product, the scroll dry vacuum pump has a very high technical content in design and production. It has obvious features such as low operating cost, long working life, high reliability and low noise in application. It has unparalleled advantages in oil cleaning applications and are therefore highly regarded by the market. The RGP series scroll dry pump is a vortex dry pump with advantages of excellent performance and competitive price , which is developed by CHINAMFG Vacuum for the downstream application of domestic and foreign markets.

Product Parameters

| Product Model | 50/60Hz | RGP3 |

| Pumping Speed | 50Hz | 12m³/H |

| 60Hz | 14.4m³/H | |

| Ultimate Pressure | mbar | 0.008 |

| Inlet Diameter | NW25 | |

| Voltage | 50Hz | 100-240 |

| 60Hz | 100-240 | |

| Motor Power | kW | 0.4 |

| Noise Level | dB | 54 |

| Net Weight | kg | 28 |

Detailed Photos

Installation Instructions

Certifications

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Oil or Not: | Oil Free |

|---|---|

| Structure: | Scroll Vacuum Pump |

| Exhauster Method: | Scroll Vacuum Pump |

| Vacuum Degree: | High Vacuum |

| Work Function: | Maintain the Pump |

| Working Conditions: | Dry |

| Samples: |

US$ 385/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can scroll vacuum pumps be integrated into existing industrial systems and processes?

Yes, scroll vacuum pumps can be integrated into existing industrial systems and processes. Here's a detailed explanation:

Scroll vacuum pumps offer several features and characteristics that make them well-suited for integration into existing industrial systems and processes:

1. Compact Design:

Scroll vacuum pumps have a compact design and a smaller footprint compared to some other types of vacuum pumps. This makes them easier to install in existing systems where space may be limited. The compact size allows for flexible placement and integration into different configurations.

2. Versatility:

Scroll vacuum pumps are versatile and can handle a wide range of applications and processes across various industries. They are compatible with processes such as vacuum deposition, drying, degassing, distillation, and more. This versatility makes it easier to integrate scroll pumps into existing systems that may have diverse process requirements.

3. Multiple Connection Options:

Scroll vacuum pumps are designed to offer multiple connection options. They typically have standard inlet and outlet connections, allowing for easy integration into existing vacuum systems or processes. These connections can be customized or adapted as needed to ensure compatibility with the existing system's piping and components.

4. Control and Monitoring Capabilities:

Many scroll vacuum pumps come with built-in control and monitoring features. These can include digital interfaces, remote control capabilities, and real-time monitoring of operating parameters. These features facilitate the integration of scroll pumps into existing industrial systems and allow for seamless communication with other system components and control systems.

5. Retrofitting Options:

In some cases, scroll vacuum pumps can be retrofitted into existing systems as a replacement for older or less efficient vacuum pumps. Retrofitting involves modifying or adapting the system to accommodate the new pump. This can be a cost-effective solution for upgrading the vacuum performance of an existing system without significant redesign or disruption.

6. Compatibility with Different Environments:

Scroll vacuum pumps are designed to operate reliably in a wide range of environments, including industrial settings. They can withstand demanding conditions such as high temperatures, humidity, or vibration, which are commonly encountered in industrial processes. This compatibility ensures that scroll pumps can seamlessly integrate into existing systems without compromising performance or reliability.

When considering the integration of scroll vacuum pumps into existing industrial systems, it is important to assess specific requirements, such as the required pumping speed, ultimate vacuum level, compatibility with process gases, and any specific environmental considerations. Consulting with the pump manufacturer or a knowledgeable supplier can provide valuable guidance on selecting the appropriate scroll pump model and optimizing its integration into the existing system.

By leveraging the compact design, versatility, connection options, control capabilities, retrofitting possibilities, and compatibility with different environments, scroll vacuum pumps can be successfully integrated into existing industrial systems and processes, enhancing their vacuum performance and overall efficiency.

Can scroll vacuum pumps be used in laboratory applications?

Yes, scroll vacuum pumps can be used in laboratory applications. Here's a detailed explanation:

Scroll vacuum pumps offer several features and advantages that make them suitable for various laboratory applications:

1. Oil-Free Operation:

Many laboratory applications require a clean and oil-free vacuum environment to maintain the integrity of samples, prevent contamination, and ensure accurate results. Scroll vacuum pumps are available in oil-free versions, eliminating the risk of oil vapor or particles contaminating the vacuum system and samples.

2. Low Vibration and Noise:

In laboratory settings where precision and sensitive measurements are crucial, low vibration and noise levels are important considerations. Scroll vacuum pumps operate with minimal vibration and produce less noise compared to some other types of vacuum pumps, making them suitable for laboratory environments.

3. Compact and Space-Efficient:

Laboratories often have limited space, and equipment that is compact and space-efficient is desirable. Scroll vacuum pumps are relatively compact in size and can be easily integrated into laboratory setups without occupying excessive space.

4. Ease of Use:

Scroll vacuum pumps are known for their user-friendly nature. They typically have simple operating procedures, require minimal adjustments or tuning, and are easy to install and operate. This is advantageous in laboratory settings where researchers and technicians may need to work with multiple instruments simultaneously.

5. Versatile Applications:

Scroll vacuum pumps find applications in a wide range of laboratory processes, including:

- Vacuum filtration

- Rotary evaporation

- Freeze drying

- Glove box systems

- Vacuum ovens

- Vacuum distillation

- Vacuum degassing

- Mass spectrometry

- Electron microscopy

- Gas chromatography

- and many more.

It's important to note that the suitability of a scroll vacuum pump for a specific laboratory application depends on the desired vacuum level, required pumping speed, compatibility with the gases or vapors being handled, and any additional requirements specific to the experimental or analytical techniques being employed.

Before selecting a scroll vacuum pump for laboratory use, it is advisable to consult the manufacturer's specifications and guidelines to ensure that the pump meets the specific requirements of the intended application.

How does the scroll design contribute to the reliability of these pumps?

The scroll design of vacuum pumps plays a significant role in enhancing their reliability. Here's an explanation of how the scroll design contributes to the reliability of these pumps:

1. Sealed System:

The scroll design features two interleaved spiral scrolls, one fixed and one orbiting. The interaction between these scrolls creates a series of crescent-shaped chambers. As the orbiting scroll moves, these chambers decrease in size, compressing and expelling gases. The tightly sealed system of the scroll design ensures minimal leakage, preventing the entry of contaminants and maintaining a consistent vacuum level. This sealed system enhances the reliability of scroll vacuum pumps by minimizing the risk of performance degradation and ensuring continuous and efficient operation.

2. Oil-Free Operation:

One of the key advantages of scroll vacuum pumps is their oil-free operation. Unlike other types of pumps that rely on oil lubrication, scroll pumps utilize a dry mechanism. The scroll design eliminates the need for oil lubrication by using non-contacting, self-lubricating materials such as PTFE (polytetrafluoroethylene) or carbon. This eliminates the risk of oil contamination in the pumped gases or the vacuum chamber. The absence of oil also reduces maintenance requirements and enhances the reliability of the pumps by eliminating the potential for oil-related issues, such as oil degradation, leaks, or mechanical failures.

3. Minimal Moving Parts:

The scroll design features a relatively simple construction with minimal moving parts. Compared to other types of pumps, scroll vacuum pumps have fewer components that can wear out or malfunction. This reduces the likelihood of mechanical failures and improves the overall reliability of the pumps. The simplicity of the scroll design also contributes to ease of maintenance and servicing, further enhancing their reliability and uptime.

4. Low Vibration and Noise Levels:

The scroll design of vacuum pumps results in smooth and quiet operation. The absence of reciprocating pistons or vanes, which are common in other pump designs, reduces vibration levels. This lower vibration minimizes the stress on pump components, reducing wear and tear and improving the overall reliability. Additionally, the low noise levels of scroll pumps make them suitable for applications that require a quiet working environment, such as laboratories or medical facilities.

5. Contamination Resistance:

The scroll design of vacuum pumps offers inherent contamination resistance. The absence of oil lubrication eliminates the risk of oil carryover or oil-related contamination. Additionally, the sealed system and non-contacting scroll surfaces reduce the chances of particulate contamination or wear debris generation. This contamination resistance contributes to the long-term reliability of the pumps by minimizing the potential for performance degradation or damage to sensitive components.

In summary, the scroll design of vacuum pumps enhances their reliability through a sealed system, oil-free operation, minimal moving parts, low vibration and noise levels, and contamination resistance. These factors make scroll vacuum pumps a reliable choice for various industrial applications.

editor by CX 2024-03-10