Product Description

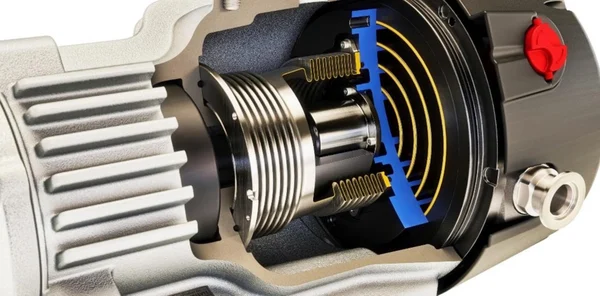

Dry Scroll Vacuum Pump RGP3

Product Description

The scroll vacuum pump is a new generation of oil-free mechanical pump, which has the advantages of simple structure, good sealing performance and high ultimate vacuum. As a high-tech product, the scroll dry vacuum pump has a very high technical content in design and production. It has obvious features such as low operating cost, long working life, high reliability and low noise in application. It has unparalleled advantages in oil cleaning applications and are therefore highly regarded by the market. The RGP series scroll dry pump is a vortex dry pump with advantages of excellent performance and competitive price , which is developed by CHINAMFG Vacuum for the downstream application of domestic and foreign markets.

Product Parameters

| Product Model | 50/60Hz | RGP3 |

| Pumping Speed | 50Hz | 12m³/H |

| 60Hz | 14.4m³/H | |

| Ultimate Pressure | mbar | 0.008 |

| Inlet Diameter | NW25 | |

| Voltage | 50Hz | 100-240 |

| 60Hz | 100-240 | |

| Motor Power | kW | 0.4 |

| Noise Level | dB | 54 |

| Net Weight | kg | 28 |

Detailed Photos

Installation Instructions

Certifications

Company Profile

| Oil or Not: | Oil Free |

|---|---|

| Structure: | Scroll Vacuum Pump |

| Exhauster Method: | Scroll Vacuum Pump |

| Vacuum Degree: | High Vacuum |

| Work Function: | Maintain the Pump |

| Working Conditions: | Dry |

| Samples: |

US$ 385/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Are there variations in scroll vacuum pump designs, and how do they affect performance?

Yes, there are variations in scroll vacuum pump designs, and they can have an impact on the performance of the pump. Here's a detailed explanation:

Single-Stage and Multi-Stage Designs:

Scroll vacuum pumps can be classified into single-stage and multi-stage designs:

- Single-stage: Single-stage scroll pumps have a single set of orbiting and fixed scrolls. They are typically used for applications where moderate vacuum levels and pumping speeds are required. Single-stage pumps are known for their simplicity, compactness, and quiet operation.

- Multi-stage: Multi-stage scroll pumps consist of multiple sets of orbiting and fixed scrolls arranged in series. Each stage provides additional compression, allowing for higher vacuum levels and faster pumping speeds. Multi-stage pumps are suitable for applications that require deeper vacuum levels or higher pumping capacities.

The choice between single-stage and multi-stage scroll pumps depends on the specific application requirements and desired performance characteristics.

Oil-Free and Oil-Sealed Designs:

Scroll vacuum pumps are available in both oil-free and oil-sealed designs:

- Oil-Free: Oil-free scroll vacuum pumps do not require lubricating oil in the pump chamber. They are suitable for applications that demand a clean and oil-free vacuum environment to prevent contamination or interference with sensitive samples or processes. Oil-free pumps are often preferred in laboratory, research, and semiconductor applications.

- Oil-Sealed: Oil-sealed scroll vacuum pumps utilize oil as a lubricant and sealing medium. The oil helps provide a better seal between the scrolls and contributes to improved performance in terms of vacuum level and pumping speed. Oil-sealed pumps are commonly used in industrial, manufacturing, and rough vacuum applications.

Both oil-free and oil-sealed scroll vacuum pumps have their advantages and considerations, and the selection depends on the specific requirements of the application.

Other Design Considerations:

In addition to the above variations, scroll vacuum pumps may have other design considerations that can affect their performance:

- Pump Size: Scroll pumps are available in different sizes, offering a range of pumping capacities and physical dimensions. The pump size influences the pumping speed and the size of the vacuum system it can handle. Smaller pumps are more compact and suitable for applications with lower flow rate requirements, while larger pumps provide higher pumping speeds.

- Motor Rating: The motor rating of a scroll vacuum pump determines its power output and affects the pumping speed and performance. Higher motor ratings generally result in faster pumping speeds and may be necessary for certain demanding applications.

- Control and Monitoring Features: Some scroll vacuum pumps may include advanced control and monitoring features, such as integrated controllers, digital interfaces, and performance indicators. These features can enhance the pump's usability, provide real-time data, and facilitate system integration.

It is important to refer to the manufacturer's specifications and guidelines for specific scroll vacuum pump models to understand the design variations and their impact on performance. The manufacturer can provide detailed information on the pump's capabilities, limitations, and recommended applications.

By selecting the appropriate scroll vacuum pump design based on the application requirements, it is possible to achieve optimal performance and efficiency in various vacuum processes.

Can scroll vacuum pumps be used in laboratory applications?

Yes, scroll vacuum pumps can be used in laboratory applications. Here's a detailed explanation:

Scroll vacuum pumps offer several features and advantages that make them suitable for various laboratory applications:

1. Oil-Free Operation:

Many laboratory applications require a clean and oil-free vacuum environment to maintain the integrity of samples, prevent contamination, and ensure accurate results. Scroll vacuum pumps are available in oil-free versions, eliminating the risk of oil vapor or particles contaminating the vacuum system and samples.

2. Low Vibration and Noise:

In laboratory settings where precision and sensitive measurements are crucial, low vibration and noise levels are important considerations. Scroll vacuum pumps operate with minimal vibration and produce less noise compared to some other types of vacuum pumps, making them suitable for laboratory environments.

3. Compact and Space-Efficient:

Laboratories often have limited space, and equipment that is compact and space-efficient is desirable. Scroll vacuum pumps are relatively compact in size and can be easily integrated into laboratory setups without occupying excessive space.

4. Ease of Use:

Scroll vacuum pumps are known for their user-friendly nature. They typically have simple operating procedures, require minimal adjustments or tuning, and are easy to install and operate. This is advantageous in laboratory settings where researchers and technicians may need to work with multiple instruments simultaneously.

5. Versatile Applications:

Scroll vacuum pumps find applications in a wide range of laboratory processes, including:

- Vacuum filtration

- Rotary evaporation

- Freeze drying

- Glove box systems

- Vacuum ovens

- Vacuum distillation

- Vacuum degassing

- Mass spectrometry

- Electron microscopy

- Gas chromatography

- and many more.

It's important to note that the suitability of a scroll vacuum pump for a specific laboratory application depends on the desired vacuum level, required pumping speed, compatibility with the gases or vapors being handled, and any additional requirements specific to the experimental or analytical techniques being employed.

Before selecting a scroll vacuum pump for laboratory use, it is advisable to consult the manufacturer's specifications and guidelines to ensure that the pump meets the specific requirements of the intended application.

editor by CX 2023-11-27