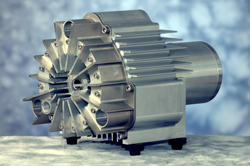

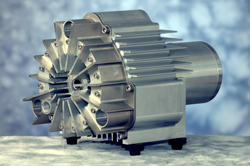

Product Description

DC Vacuum Pump Rotary Portable Industrial Mini Vane Scroll Reciprocating Diaphragm Centrifugal Positive Displacement Best Suppliers DC AC Vacuum Pump

Micro-pump is powered miniature DC motor drive, drive internal mechanical eccentric eccentric motion, driven by an eccentric movement inside the diaphragm reciprocates. Whereby the pump chamber fixed volume of air compression (compression suction port is closed, the exhaust port is formed to open slightly positive pressure), stretching (compressed exhaust port is closed, a negative pressure sucking mouth open), the pumping air intakes with the outside atmospheric pressure difference, at a pressure difference, the gas pressure (suction) into the pump chamber, and discharged from the exhaust port.

-Micro-pump is mainly used for medicine, gas analysis sampling, instrumentation and other fields. Completely maintenance-free, and no oil pump, do not pollute the transmission medium.

-Small, stable and reliable, hand-held instrument for pump-priming, low noise, low power consumption. Especially -suitable for high negative environmental requirements.

Specification:

Operating voltage: DC9V ~ 14V

Rated voltage: DC 12V

Current Rating: 500mA

Power Rating: 6W

Vacuum degree: 65kpa

Maximum pressure: 120kpa

Noise: <60db

company information

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Installation Guide 1-Year Warranty |

|---|---|

| Warranty: | Installation Guide 1-Year Warranty |

| Oil or Not: | Optional |

| Structure: | - |

| Exhauster Method: | - |

| Vacuum Degree: | - |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | |

|---|

Are scroll vacuum pumps environmentally friendly and compliant with regulations?

Scroll vacuum pumps are considered relatively environmentally friendly compared to some other types of vacuum pumps. Here's a detailed explanation:

Environmental Friendliness:

Scroll vacuum pumps offer several features that contribute to their environmental friendliness:

- Oil-Free Operation: Many scroll vacuum pumps are designed for oil-free operation. This eliminates the risk of oil contamination and the release of oil vapor or aerosols into the environment. Oil-free operation is particularly important in applications where a clean and particle-free vacuum environment is required, such as semiconductor manufacturing or research.

- Low Energy Consumption: Scroll pumps are known for their energy efficiency. They typically consume less energy compared to other vacuum pump technologies, resulting in reduced power consumption and lower environmental impact.

- Minimal Maintenance: Scroll vacuum pumps require minimal maintenance, which reduces the consumption of resources and minimizes waste generation associated with pump servicing or component replacement.

- Quiet Operation: Scroll pumps are designed to operate quietly, contributing to a more comfortable and environmentally friendly working environment by reducing noise pollution.

Regulatory Compliance:

Scroll vacuum pumps are designed and manufactured to comply with various regulations and standards, ensuring their safe and environmentally responsible operation. Some of the key regulations and standards that govern vacuum pumps include:

- European Union (EU) Regulations: Scroll vacuum pumps intended for sale or use within the European Union must comply with relevant directives, such as the Restriction of Hazardous Substances (RoHS) Directive and the Waste Electrical and Electronic Equipment (WEEE) Directive. These directives restrict the use of hazardous substances and promote the proper disposal and recycling of electronic equipment.

- International Electrotechnical Commission (IEC) Standards: IEC standards, such as IEC 61010 for electrical safety and IEC 61326 for electromagnetic compatibility, provide guidelines for the safe operation and performance of vacuum pumps and other laboratory equipment.

- Environmental Protection Agency (EPA) Regulations (United States): In the United States, scroll vacuum pumps must comply with environmental regulations enforced by the EPA, such as the Clean Air Act. These regulations aim to reduce emissions of ozone-depleting substances and other pollutants.

- Local and National Regulations: Depending on the jurisdiction, there may be additional local or national regulations governing the use, disposal, or emissions of vacuum pumps. Manufacturers ensure compliance with these regulations to meet the requirements of specific markets.

It is important to consult the manufacturer's specifications, certifications, and compliance statements to ensure that a particular scroll vacuum pump model meets the necessary environmental and regulatory standards for a given application or jurisdiction.

By choosing scroll vacuum pumps with oil-free operation, energy efficiency, minimal maintenance requirements, and compliance with regulations, users can contribute to a more environmentally friendly and sustainable vacuum system.

Are there oil-free options available for scroll vacuum pumps?

Yes, there are oil-free options available for scroll vacuum pumps. Here's a detailed explanation:

Traditionally, scroll vacuum pumps have utilized oil lubrication for sealing and bearing purposes. However, due to the increasing demand for oil-free vacuum solutions in various industries, manufacturers have developed oil-free versions of scroll vacuum pumps.

Oil-Free Scroll Vacuum Pumps:

Oil-free scroll vacuum pumps are designed to operate without the need for oil lubrication. Instead of relying on oil to create a seal and reduce internal friction, these pumps utilize dry-running mechanisms and specialized sealing materials to achieve reliable and efficient vacuum performance.

Advantages of Oil-Free Scroll Vacuum Pumps:

Oil-free scroll vacuum pumps offer several advantages, including:

a. Elimination of Oil Contamination: By eliminating oil lubrication, oil-free scroll vacuum pumps prevent the risk of oil contamination in the pumped gases or the surrounding environment. This is particularly important in applications where oil vapor or particles can adversely affect the process or product being handled.

b. Reduced Maintenance: Oil-free scroll vacuum pumps generally require less maintenance compared to their oil-lubricated counterparts. Without the need for oil changes, oil monitoring, or oil-related maintenance tasks, the overall maintenance requirements are simplified.

c. Environmentally Friendly: Oil-free scroll vacuum pumps are considered more environmentally friendly as they eliminate the need for oil disposal or recycling. They help reduce the carbon footprint and minimize the impact on the ecosystem.

d. Cost Savings: While the initial purchase cost of oil-free scroll vacuum pumps may be higher compared to oil-lubricated models, the long-term cost savings can be significant. The elimination of oil-related maintenance, reduced downtime, and improved process efficiency can result in overall cost savings.

Applications of Oil-Free Scroll Vacuum Pumps:

Oil-free scroll vacuum pumps find applications in various industries and processes, including:

- Semiconductor manufacturing - Analytical instruments - Pharmaceuticals and biotechnology - Food and beverage packaging - Electronics assembly - Research laboratories - Environmental monitoring - Vacuum drying - Leak detection - and more.

It's important to note that while oil-free scroll vacuum pumps offer numerous advantages, their performance specifications, such as pumping speed and ultimate vacuum levels, may differ from oil-lubricated scroll pumps. It's essential to select the appropriate pump based on the specific application requirements and consult the manufacturer's guidelines for proper operation and maintenance.

What are the typical applications of scroll vacuum pumps across industries?

Scroll vacuum pumps find applications in a wide range of industries due to their unique advantages and capabilities. Here's a detailed explanation of the typical applications of scroll vacuum pumps across various industries:

1. Laboratories and Research Facilities:

Scroll vacuum pumps are extensively used in laboratories and research facilities for various applications. They are commonly employed in vacuum ovens, freeze dryers, rotary evaporators, and other laboratory equipment that require precise and controlled vacuum environments. Scroll pumps' oil-free operation ensures a clean and contamination-free atmosphere, making them suitable for sensitive experiments and analyses. Their low noise and vibration levels are also advantageous in research settings where a quiet environment is necessary.

2. Semiconductor Manufacturing:

In the semiconductor industry, scroll vacuum pumps play a crucial role in the fabrication and production of electronic components. They are used in processes such as physical vapor deposition (PVD), chemical vapor deposition (CVD), etching, and ion implantation. Scroll pumps provide the required vacuum conditions for these processes, ensuring the deposition or removal of materials with high precision. Their oil-free operation eliminates the risk of oil contamination in the semiconductor manufacturing process, ensuring the quality and reliability of the manufactured devices.

3. Analytical Instruments:

Scroll vacuum pumps are widely used in analytical instruments such as mass spectrometers, electron microscopes, and surface analysis equipment. These instruments require vacuum environments to operate efficiently and produce accurate results. Scroll pumps offer the necessary vacuum levels for sample preparation, ionization, and analysis. Their high pumping speed and deep vacuum capabilities make them suitable for rapid evacuation and maintaining the required vacuum conditions during analytical processes.

4. Medical and Pharmaceutical Applications:

In the medical and pharmaceutical industries, scroll vacuum pumps find applications in various areas. They are commonly used in medical sterilizers, vacuum ovens for drying pharmaceutical products, and vacuum concentrators for sample preparation. The oil-free operation of scroll pumps ensures the integrity and quality of medical devices, pharmaceutical products, and biological samples. Their low noise levels and compact size are advantageous in medical environments where space is limited, and a quiet atmosphere is necessary.

5. Food Processing and Packaging:

Scroll vacuum pumps are employed in the food processing and packaging industry for vacuum packaging, vacuum sealing, and degassing processes. They help extend the shelf life of food products by creating a vacuum environment that inhibits microbial growth and prevents oxidation. Scroll pumps are also used in food freeze-drying processes to remove moisture while maintaining the product's quality and nutritional value. Their clean and oil-free operation ensures the hygiene and safety of the food products.

6. Environmental and HVAC Systems:

Scroll vacuum pumps are used in environmental monitoring systems where they help create vacuum conditions for gas analysis and air quality measurement. They are also utilized in heating, ventilation, and air conditioning (HVAC) systems for vacuum evacuation during the installation or maintenance of HVAC units. The compact size and low noise levels of scroll pumps make them suitable for HVAC applications where space constraints and noise reduction are important considerations.

7. Automotive and Manufacturing:

In the automotive and manufacturing industries, scroll vacuum pumps find applications in processes such as vacuum molding, vacuum lifting, and vacuum forming. They provide the necessary vacuum conditions for molding or shaping materials, lifting heavy objects, and creating airtight seals. The oil-free operation of scroll pumps ensures that there is no risk of oil contamination in the manufactured products.

These are just a few examples of the typical applications of scroll vacuum pumps across industries. Their oil-free operation, high efficiency, low noise levels, and clean vacuum generation make them a versatile and reliable choice in various industrial sectors.

editor by CX 2024-02-21