Product Description

Product Description

GWSP Oil free Scroll Vacuum Pump

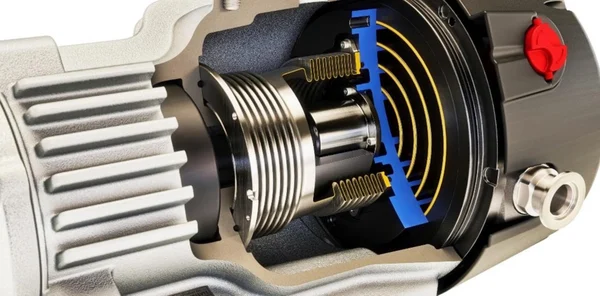

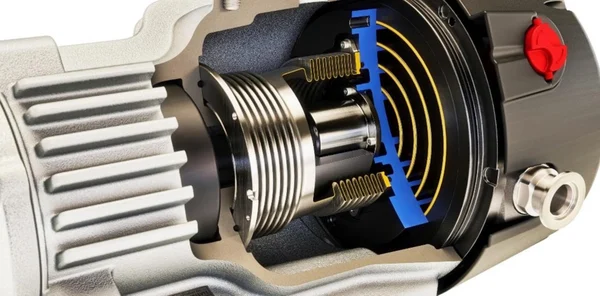

Working principle:

GWSP oil free scroll vacuum pump is constructed with pump head assembly, crank pin assembly, bracket assembly, air flush assembly,and exhaust valve assembly.Two spiral cylinders, 1 offset and orbiting against the other fixed with an offset of 180° to form several crescent-shaped pockets of different sizes. By means of an eccentric drive, the orbiting scroll is made to orbit about the fixed scroll, reducing the volume of the pockets and compressing gas from outside towards the inside thereby pumping the gas from vacuum chamber.

Basic informations:

1) Model: GWSP600 Oil free scroll vacuum pump

2) Ultimate vacuum pressure: 1 Pa/0.01 mbar (abs.)

3) Max suction capacity: 50Hz-8.7L/s 60Hz-10.4L/s

Safety Precautions:

The GWSP series oil free scroll vacuum pumps are suitable for clean processes only.

Do not pump toxic, explosive, flammable or corrosive substances or substances which contain chemicals, solvents or particles.GEOWELL will not perform maintenance work on pumps which have used special gases or other hazardous substances.

Be sure the inlet gas temperature must be lower than 122 °F.

Technical Specifications

| Model | GWSP40 | GWSP75 | GWSP150 | GWSP300 | GWSP600 | GWSP1000 | ||

| Displacement | 50Hz | l/s | 0.5 | 1.0 | 2.0 | 4.3 | 8.7 | 16.6 |

| m3/h | 1.8 | 3.6 | 7.2 | 15.5 | 31.3 | 59.8 | ||

| cfm | 1.1 | 2.1 | 4.3 | 9.3 | 18.7 | 35.8 | ||

| 60Hz | l/s | 0.6 | 1.2 | 2.4 | 5.1 | 10.4 | 20.0 | |

| m3/h | 2.2 | 4.3 | 8.6 | 18.3 | 37.4 | 71.6 | ||

| cfm | 1.3 | 2.5 | 5.1 | 10.9 | 22.3 | 42.8 | ||

| Ultimate Pressure | Torr | ≤1.1*10-1 | ≤6.0*10-2 | ≤4.5*10-2 | ≤1.9*10-2 | ≤7.5*10-3 | ≤7.5*10-3 | |

| psi | ≤2.2*10-3 | ≤1.2*10-3 | ≤9.0*10-4 | ≤3.8*10-4 | ≤1.5*10-4 | ≤1.5*10-4 | ||

| Pa | ≤15 | ≤8 | ≤6 | ≤2.6 | ≤1 | ≤1 | ||

| mbar | ≤1.5*10-1 | ≤8.0*10-2 | ≤6.0*10-2 | ≤2.6*10-2 | ≤1.0*10-2 | ≤1.0*10-2 | ||

| Noise Level | dB(A) | ≤54 | ≤57 | ≤57 | ≤60 | ≤61 | ≤65 | |

| Leakage | mbar·l/s | 1*10-7 | ||||||

| Max. Inlet/Exhaust Pressure | MPa | 0.1 / 0.13 | ||||||

| Ambient Operation Temp. | ºF | 41~104 | ||||||

| Motor 1 phase | Power | kW | 0.25 | 0.55 | 0.55 | 0.55 | 0.75 | -- |

| Voltage | V | 110~115 (60Hz),200~230 (50Hz) | -- | |||||

| Speed | rpm | 1425(50Hz),1725(60Hz) | -- | |||||

| Plug | North America, Europe, UK/Ireland, India | -- | ||||||

| Motor 3 phase | Power | kW | -- | 0.55 | 0.55 | 0.55 | 0.75 | 1.5 |

| Voltage | V | -- | 200~230 or 380~415 (50Hz),200~230 or 460 (60Hz) | |||||

| Speed | rpm | -- | 1425 (50Hz),1725 (60Hz) | |||||

| Inlet/Exhaust Flange | KF25/KF16 | KF40/KF16 | KF40/KF16*2 | |||||

| Dimensions | 1 phase | mm | 326*212*253 | 450*260*296 | 455*260*296 | 493*297*334 | 538*315*348 | -- |

| 3 phase | mm | -- | 450*260*296 | 455*260*296 | 493*297*334 | 538*315*348 | 576*450*402 | |

| Net Weight | 1 phase | kg | 15 | 21 | 22 | 29 | 36 | -- |

| 3 phase | kg | -- | 20 | 21 | 28 | 31 | 54 | |

| Cooling Type | Air cooled | |||||||

| Others | With air flush | |||||||

Features & Benefits

No oil clean vacuum.

No oil back-diffusion, no oil mist exhaust, provide clean vacuum environment

Wide product lineup.

Pumping speed covers 3~60 m3 /h, limited vacuum level 1~8 Pa

Suitable for all type of power supply around the world.

110/220/380/460V, 50/60Hz for choose

Low vibration, low noise.

57~65 dB(A), smooth operation

High efficiency, ease of maintenance.

No water cooled, no oil lubricated, no daily maintenance

Quality Control

CMM inspection system assures

fixed tolarance on dimension&shape

Pump Testing

Applications

Semiconductor industryindustry.stry

Vacuum sputtering machine.

IC plasma cleaning machine.

IC plasma polishing machine.

IC packaging machine.

IC transmission chamber.

Photoelectric industry.

LED vacuum annealing furnace.

Load lock/transfer chambers.

Glove box.

LED packaging machine.

Liquid crystal injection and packaging.

Material industry.

Vacuum annealing furnace.

Vacuum diffusion oven.

3D metal printing.

Single crystal growth furnace.

Microwave cleaning and microwave drying machine.

E-beam/Laser melting.

Vacuum degassing.

Vacuum gas substitution.

Vacuum equipment.

Oil free ultrahigh vacuum unit.

Oil free vacuum unit.

Company Profile

GEOWELL VACUUM CO.,LTD. is a HI-TECH enterprise in China dedicating in manufacturing, research and development, marketing of oil free scroll vacuum pumps and vacuum compressors since 2002. GEOWELL has been providing users and partners with premium quality products that are efficient and dependable, GEOWELL believe the integration of high performance and high reliability product and service will bring the highest value to both our customers and ourselves.

FAQ

Q: How long can I get the feedback after we sent the inquiry?

A: We will reply you within 12 hours in working day.

Q: Are you direct manufacturer?

A: Yes, we are direct manufacturer with factory and international department; we manufacture and sell all our products by ourselves.

Q: When can you delivery the product to us?

A: Since we are a factory with large warehouse, we have abundant products in store, so we can delivery within 7 days after get your deposit.

Q: Can I add logo to the products?

A: Of course, but we usually have quantity requirement. You can contact with us for details.

Q: How to guarantee the quality and after sales service of your products?

A: We conduct strict detection during production from raw material come in to product delivering shipment. Every product must go through 4 steps inspection from casting, machining, assembling, and performance testing within our factory before shipment, also intact packaging test are insured.

Q: What is your warranty term?

A: There is a 12 months warranty for our export products from the date of shipment. If warranty has run out, our customer should pay for the replacement part.

Q: Is the sample available?

A: Yes, usually we send our samples by Fedex, DHL, TNT, UPS, EMS, SF, Depon, it will take around 3 to 4 days for our customer receive them, but customer will charge all cost related to the samples, such as sample cost and air freight. We will refund our customer the sample cost after receiving the order.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Yes |

|---|---|

| Warranty: | 1 Years |

| Oil or Not: | Oil Free |

| Structure: | Scroll Pump |

| Exhauster Method: | a Pair of Vortex Plates |

| Vacuum Degree: | Low Vacuum |

| Customization: |

Available

|

|

|---|

Can scroll vacuum pumps be integrated into existing industrial systems and processes?

Yes, scroll vacuum pumps can be integrated into existing industrial systems and processes. Here's a detailed explanation:

Scroll vacuum pumps offer several features and characteristics that make them well-suited for integration into existing industrial systems and processes:

1. Compact Design:

Scroll vacuum pumps have a compact design and a smaller footprint compared to some other types of vacuum pumps. This makes them easier to install in existing systems where space may be limited. The compact size allows for flexible placement and integration into different configurations.

2. Versatility:

Scroll vacuum pumps are versatile and can handle a wide range of applications and processes across various industries. They are compatible with processes such as vacuum deposition, drying, degassing, distillation, and more. This versatility makes it easier to integrate scroll pumps into existing systems that may have diverse process requirements.

3. Multiple Connection Options:

Scroll vacuum pumps are designed to offer multiple connection options. They typically have standard inlet and outlet connections, allowing for easy integration into existing vacuum systems or processes. These connections can be customized or adapted as needed to ensure compatibility with the existing system's piping and components.

4. Control and Monitoring Capabilities:

Many scroll vacuum pumps come with built-in control and monitoring features. These can include digital interfaces, remote control capabilities, and real-time monitoring of operating parameters. These features facilitate the integration of scroll pumps into existing industrial systems and allow for seamless communication with other system components and control systems.

5. Retrofitting Options:

In some cases, scroll vacuum pumps can be retrofitted into existing systems as a replacement for older or less efficient vacuum pumps. Retrofitting involves modifying or adapting the system to accommodate the new pump. This can be a cost-effective solution for upgrading the vacuum performance of an existing system without significant redesign or disruption.

6. Compatibility with Different Environments:

Scroll vacuum pumps are designed to operate reliably in a wide range of environments, including industrial settings. They can withstand demanding conditions such as high temperatures, humidity, or vibration, which are commonly encountered in industrial processes. This compatibility ensures that scroll pumps can seamlessly integrate into existing systems without compromising performance or reliability.

When considering the integration of scroll vacuum pumps into existing industrial systems, it is important to assess specific requirements, such as the required pumping speed, ultimate vacuum level, compatibility with process gases, and any specific environmental considerations. Consulting with the pump manufacturer or a knowledgeable supplier can provide valuable guidance on selecting the appropriate scroll pump model and optimizing its integration into the existing system.

By leveraging the compact design, versatility, connection options, control capabilities, retrofitting possibilities, and compatibility with different environments, scroll vacuum pumps can be successfully integrated into existing industrial systems and processes, enhancing their vacuum performance and overall efficiency.

Are there oil-free options available for scroll vacuum pumps?

Yes, there are oil-free options available for scroll vacuum pumps. Here's a detailed explanation:

Traditionally, scroll vacuum pumps have utilized oil lubrication for sealing and bearing purposes. However, due to the increasing demand for oil-free vacuum solutions in various industries, manufacturers have developed oil-free versions of scroll vacuum pumps.

Oil-Free Scroll Vacuum Pumps:

Oil-free scroll vacuum pumps are designed to operate without the need for oil lubrication. Instead of relying on oil to create a seal and reduce internal friction, these pumps utilize dry-running mechanisms and specialized sealing materials to achieve reliable and efficient vacuum performance.

Advantages of Oil-Free Scroll Vacuum Pumps:

Oil-free scroll vacuum pumps offer several advantages, including:

a. Elimination of Oil Contamination: By eliminating oil lubrication, oil-free scroll vacuum pumps prevent the risk of oil contamination in the pumped gases or the surrounding environment. This is particularly important in applications where oil vapor or particles can adversely affect the process or product being handled.

b. Reduced Maintenance: Oil-free scroll vacuum pumps generally require less maintenance compared to their oil-lubricated counterparts. Without the need for oil changes, oil monitoring, or oil-related maintenance tasks, the overall maintenance requirements are simplified.

c. Environmentally Friendly: Oil-free scroll vacuum pumps are considered more environmentally friendly as they eliminate the need for oil disposal or recycling. They help reduce the carbon footprint and minimize the impact on the ecosystem.

d. Cost Savings: While the initial purchase cost of oil-free scroll vacuum pumps may be higher compared to oil-lubricated models, the long-term cost savings can be significant. The elimination of oil-related maintenance, reduced downtime, and improved process efficiency can result in overall cost savings.

Applications of Oil-Free Scroll Vacuum Pumps:

Oil-free scroll vacuum pumps find applications in various industries and processes, including:

- Semiconductor manufacturing - Analytical instruments - Pharmaceuticals and biotechnology - Food and beverage packaging - Electronics assembly - Research laboratories - Environmental monitoring - Vacuum drying - Leak detection - and more.

It's important to note that while oil-free scroll vacuum pumps offer numerous advantages, their performance specifications, such as pumping speed and ultimate vacuum levels, may differ from oil-lubricated scroll pumps. It's essential to select the appropriate pump based on the specific application requirements and consult the manufacturer's guidelines for proper operation and maintenance.

What is a scroll vacuum pump, and how does it work?

A scroll vacuum pump is a type of positive displacement pump used to create a vacuum by removing gases or air from a sealed system. It operates based on the principle of two interlocking spiral-shaped scrolls or spirals that create a series of enclosed pockets or chambers. Here's a detailed explanation of how a scroll vacuum pump works:

1. Basic Design:

A scroll vacuum pump typically consists of two main components: a fixed scroll and an orbiting scroll. The fixed scroll remains stationary, while the orbiting scroll moves eccentrically within the fixed scroll. Both scrolls have interlocking profiles, and the shape of the profiles determines the operation of the pump.

2. Suction Stage:

At the start of the operation, the scrolls are in the outermost position, and the chambers between the scrolls are open to the inlet or suction side of the pump. As the orbiting scroll begins to rotate, it moves inward, causing the chambers to decrease in volume. This reduction in volume creates a suction effect, drawing the gas or air into the chambers from the inlet port. The suction stage is responsible for pulling the gas or air into the pump.

3. Compression Stage:

As the orbiting scroll continues to rotate, the chambers move toward the center of the scrolls, progressively reducing in size. This reduction in chamber volume compresses the gas or air trapped within the chambers. The gas or air becomes trapped between the scrolls as they interlock and move closer together. The compression stage increases the pressure within the trapped gas or air, progressively compressing it as the scrolls continue to rotate.

4. Discharge Stage:

Once the chambers reach the center of the scrolls, they move to the outermost position on the discharge side of the pump. At this stage, the compressed gas or air is forced out of the pump through the discharge port. The discharge stage completes a full rotation of the scrolls, expelling the compressed gas or air from the pump, creating a vacuum within the system.

5. Oil-Free Operation:

One significant advantage of scroll vacuum pumps is their oil-free operation. Unlike some other vacuum pump types, scroll pumps do not require oil for lubrication or sealing purposes. The interlocking scrolls create a sealing mechanism without the need for any lubricating medium. This oil-free operation eliminates the risk of oil contamination in sensitive applications and reduces maintenance requirements.

6. Efficiency and Noise:

Scroll vacuum pumps are known for their efficiency and low noise levels. The continuous spiral motion of the scrolls ensures smooth and quiet operation. Additionally, the absence of frictional parts and the use of precise manufacturing techniques contribute to their overall efficiency. Scroll pumps can achieve high pumping speeds and deep vacuum levels, making them suitable for various applications.

7. Applications:

Scroll vacuum pumps find applications in a wide range of industries. They are commonly used in laboratories, medical equipment, semiconductor manufacturing, analytical instruments, and other industries that require clean, oil-free vacuum systems. Their compact size, reliability, and low maintenance make them a popular choice in applications where quiet operation and minimal vibration are essential.

In summary, a scroll vacuum pump operates by using two interlocking scrolls to create a series of chambers that progressively decrease in volume, leading to gas or air suction, compression, and discharge. The oil-free operation, efficiency, low noise levels, and suitability for various applications make scroll vacuum pumps a widely used and reliable vacuum solution.

editor by CX 2024-04-12