Product Description

Technical Parameters

If you want to obtain more parameter information, please contact us

Product Overview

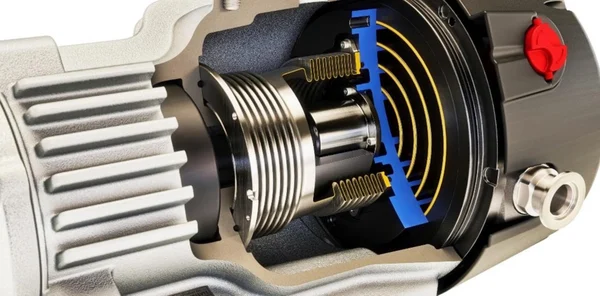

Grease lubricated molecular pump is a kind of mechanical vacuum pump which achieves pumping through the relative high speed rotation of multi-stage dynamic and static turbine vanes. This turbine molecular pump has the characteristics of large pumping speed and high compression ratio in the molecular flow area, and it is more energy-saving than diffusion pump and no oil vapor pollution.

Why Choose Us

About US

Our factory is a designated internship base of ZheJiang HangZhou University and a scientific research enterprise of East China University of Technology. Each production line of the factory is equipped with imported advanced equipment to ensure the continuous stability of product quality, and continuously innovate and develop products in the vacuum field to provide customers with superior quality Of vacuum products.

Packaging & Shipping

Related Products

Exhibition

FAQ

|

Frequently Asked Questions (FAQ) About Our Products 1-What types of vacuum pumps do you offer? We supply a wide range of vacuum pumps, including rotary vane, diaphragm, screw, and turbo molecular pump, suitable for various applications. 2-Can your vacuum valves be used in any installation? Our vacuum valves, including gate, ball, butterfly, and check valves, are designed for versatility across numerous vacuum installations. Please consult our sales engineers for the best fit for your system. 3-Do you provide custom vacuum components? Yes, we can supply custom vacuum components tailored to your specific requirements. Contact us with your specifications for further assistance. Ordering and Shipping 4-How can I place an order? Orders can be placed directly through our website, via email, or by contacting our sales team. 5-Do you ship internationally? Absolutely! We provide global shipping options. Shipping costs and times will vary depending on your location and the size of your order. 6-What payment methods do you accept? We accept various payment methods, including bank transfers, credit/debit cards, and select online payment platforms. Please consult our sales team. Technical Support and Services 7-Do you offer installation services for your products? While we primarily supply vacuum products, we can recommend trusted partners for installation services. For certain regions, installation consultation may be available. Please consult our sales team for the details. 8-How can I get technical support for a product? Technical support is available through our website's support section, via email, or by phone. Our team of experts is ready to assist you with any queries or issues. Miscellaneous 9-How can I receive updates on new products and promotions? You can subscribe to our newsletter through our website to receive the latest product updates and promotional offers. 10-Do you offer discounts for bulk orders? Yes, we offer discounts for bulk orders. Please contact our sales team for more information on bulk order pricing. 11-How can I become a distributor for your products? We're always looking to expand our distribution network. If you're interested in becoming a distributor, please contact us to discuss the application process. |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Warranty: | 1 Year |

|---|---|

| Inlet Flange: | ISO-K160 or CF150 |

| Power Source: | Electric |

| Lubrication: | Grease |

| Certification: | ISO9001 |

| Voltage: | 220V/380V |

| Samples: |

US$ 4000/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can scroll vacuum pumps be integrated into existing industrial systems and processes?

Yes, scroll vacuum pumps can be integrated into existing industrial systems and processes. Here's a detailed explanation:

Scroll vacuum pumps offer several features and characteristics that make them well-suited for integration into existing industrial systems and processes:

1. Compact Design:

Scroll vacuum pumps have a compact design and a smaller footprint compared to some other types of vacuum pumps. This makes them easier to install in existing systems where space may be limited. The compact size allows for flexible placement and integration into different configurations.

2. Versatility:

Scroll vacuum pumps are versatile and can handle a wide range of applications and processes across various industries. They are compatible with processes such as vacuum deposition, drying, degassing, distillation, and more. This versatility makes it easier to integrate scroll pumps into existing systems that may have diverse process requirements.

3. Multiple Connection Options:

Scroll vacuum pumps are designed to offer multiple connection options. They typically have standard inlet and outlet connections, allowing for easy integration into existing vacuum systems or processes. These connections can be customized or adapted as needed to ensure compatibility with the existing system's piping and components.

4. Control and Monitoring Capabilities:

Many scroll vacuum pumps come with built-in control and monitoring features. These can include digital interfaces, remote control capabilities, and real-time monitoring of operating parameters. These features facilitate the integration of scroll pumps into existing industrial systems and allow for seamless communication with other system components and control systems.

5. Retrofitting Options:

In some cases, scroll vacuum pumps can be retrofitted into existing systems as a replacement for older or less efficient vacuum pumps. Retrofitting involves modifying or adapting the system to accommodate the new pump. This can be a cost-effective solution for upgrading the vacuum performance of an existing system without significant redesign or disruption.

6. Compatibility with Different Environments:

Scroll vacuum pumps are designed to operate reliably in a wide range of environments, including industrial settings. They can withstand demanding conditions such as high temperatures, humidity, or vibration, which are commonly encountered in industrial processes. This compatibility ensures that scroll pumps can seamlessly integrate into existing systems without compromising performance or reliability.

When considering the integration of scroll vacuum pumps into existing industrial systems, it is important to assess specific requirements, such as the required pumping speed, ultimate vacuum level, compatibility with process gases, and any specific environmental considerations. Consulting with the pump manufacturer or a knowledgeable supplier can provide valuable guidance on selecting the appropriate scroll pump model and optimizing its integration into the existing system.

By leveraging the compact design, versatility, connection options, control capabilities, retrofitting possibilities, and compatibility with different environments, scroll vacuum pumps can be successfully integrated into existing industrial systems and processes, enhancing their vacuum performance and overall efficiency.

Do scroll vacuum pumps require water cooling or air cooling systems?

Scroll vacuum pumps can be designed to utilize either water cooling or air cooling systems. Here's a detailed explanation:

Water Cooling Systems:

Some scroll vacuum pumps are equipped with water cooling systems to dissipate the heat generated during operation. Water cooling offers efficient heat removal and helps maintain the pump at optimal operating temperatures. These pumps typically have connections for water inlet and outlet, allowing the circulation of cooling water through the pump's heat exchanger or jacket.

Water cooling systems are commonly used in applications where the pump operates at higher duty cycles or when the ambient temperature is relatively high. They are particularly advantageous when there is a need for continuous or extended operation at elevated vacuum levels, as water cooling provides effective heat dissipation and prevents overheating of the pump.

Air Cooling Systems:

Alternatively, some scroll vacuum pumps utilize air cooling systems. These pumps rely on the circulation of ambient air to dissipate the heat generated during operation. Air cooling systems typically incorporate cooling fins or fans to enhance heat transfer and maintain the pump within the acceptable temperature range.

Air cooling systems are commonly used in applications where water availability or infrastructure is limited. They are suitable for situations where the pump duty cycle is lower, and the operating conditions do not result in excessive heat generation.

Selection Considerations:

When choosing between water cooling and air cooling systems for a scroll vacuum pump, several factors should be considered:

- Duty Cycle: The duty cycle of the pump, which refers to the ratio of operating time to resting time, can influence the heat generation. Higher duty cycles may require water cooling for efficient heat dissipation.

- Operating Environment: The ambient temperature and availability of water resources in the operating environment should be assessed. Water cooling may be preferred in high-temperature environments or when water is readily available.

- Application Requirements: The specific requirements of the application, including desired vacuum level, pumping speed, and operating conditions, should be considered to determine the appropriate cooling system.

- Maintenance and Infrastructure: The availability of maintenance resources, infrastructure for water circulation, and any specific facility requirements should be evaluated when selecting the cooling system.

It's essential to consult the manufacturer's specifications and guidelines to determine the recommended cooling system for a particular scroll vacuum pump model. This ensures optimal performance, longevity, and reliability of the pump in the intended application.

What is the noise level produced by scroll vacuum pumps during operation?

The noise level produced by scroll vacuum pumps during operation is typically low. Here's a detailed explanation:

1. Quiet Operation:

Scroll vacuum pumps are known for their quiet operation compared to other types of pumps. The absence of reciprocating parts, such as pistons or vanes, which generate noise through mechanical contact, contributes to their low noise levels. Scroll pumps operate with a smooth and continuous rotary motion, resulting in reduced noise production.

2. Noise Measurements:

The noise level of a scroll vacuum pump is measured in decibels (dB). The specific noise level can vary depending on factors such as the pump model, size, and operating conditions. However, most scroll vacuum pumps produce noise levels in the range of 50 dB to 70 dB.

3. Noise Reduction:

Manufacturers of scroll vacuum pumps often incorporate noise reduction features and technologies to further minimize noise levels. These may include vibration isolation mounts, sound-dampening materials, and optimized airflow designs. These measures help to attenuate noise and ensure quieter operation.

4. Application Considerations:

The noise level requirements may vary depending on the specific application. In some sensitive environments, such as laboratories, research facilities, or medical settings, a low-noise environment is essential to maintain concentration, precision, or patient comfort. Scroll vacuum pumps, with their inherently quiet operation, are well-suited for such applications.

5. Noise Control:

In cases where further noise reduction is necessary, additional noise control measures can be implemented. These may include enclosing the pump in a soundproof housing or utilizing acoustic insulation materials to further dampen the noise. It's important to consider the specific requirements of the application and consult the manufacturer or a noise control expert for guidance on implementing appropriate noise reduction strategies.

In summary, scroll vacuum pumps are known for their quiet operation, typically producing noise levels in the range of 50 dB to 70 dB. Their low noise levels make them suitable for environments where a low-noise working environment is desired, such as laboratories, research facilities, and medical settings. Additionally, manufacturers may incorporate noise reduction features to further minimize noise levels. Overall, scroll vacuum pumps offer a favorable noise profile for various applications.

editor by CX 2024-04-10